A TEC Production & Service GmbH products

Products & Processes - Spare Parts

A-TEC - Spare Parts

Getting first class spare parts to you on time is of strategic importance. That is why the supply of spare parts has top priority at A TEC. This applies not only to their procurement, but also to their transport and installation. Our Spare Parts team will be glad to assist you with mapping out a strategy for your specific requirements. Our spare parts management is a service with many facets.

Products & Processes - Products

A TEC - Rocket Mill

The Rocket Mill is A TEC’s innovation for alternative fuel preparation which combines drying, grinding and homogenising in one step. Permanent control of the mill power guarantees optimum and secure utilization. The input material usually only requires one pre-shredding step followed by a sieving step, which is sorting out the organic,and a magnetic separation.

A-TEC - Pendulum Flap

Pendulum Flaps in cement preheaters have the function to avoid counter gas flow through material pipes between two stages of the preheater. Such counter gas flow leads to unwanted heat loss and build-up formation in meal ducts and results in drastic reduction of the separation efficiency of the cyclone above.

A-TEC - Splash Box

Optimized distribution of the feed into the riser ducts of cement kilns is a key factor for optimized heat exchange and thermal efficiency of the pyroprocess. The engineering team of A TEC has designed a special SPLASH BOX to avoid a poor degree of calcination of the raw material, high exit temperature at the preheater top stage and consequently higher specific energy consumption (kcal/ kg clinker) as well as poor clinker quality.

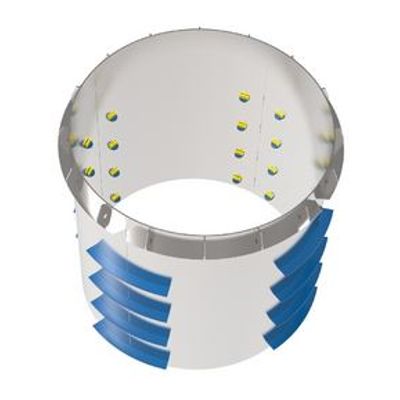

A-TEC - Cyclone Dip Tube

Cyclone Immersion (Dip) Tube for Preheater Lower Stages. Dip tubes have significant influence on the separation efficiency of a cyclone. In modern suspension preheaters it is standard to use cyclones with a dip tube for improved separation. Especially the design of a lower stage dip tube requires know-how and expertise in order to achieve a low pressure drop of the cyclone by retaining the best possible separation efficiency (to avoid too high dust circulation). The choice of material is of great importance due to high operating temperatures, abrasive material and often existing chemical conditions.

A-TEC - Tertiary Air Duct Slide Gate

The nearly maintenance free tertiary air duct slide gate provides the regulation of the gas flow between tertiary air duct and the kiln.

Hurriclon - Low Pressure High Efficiency Cyclone

A TEC cyclones stand for best efficiency, best pressure drop reduction, less space requirement. The Low Pressure High Efficiency Cyclone is a cyclone of the “next generation”. It is based on the technically superior characteristics of the double dip tube design combined with the integrated HURRIVANE® technology.