ABC Machinery products

Air Flow Dryer

This air flow dryer is to torrefy the material with higher moisture. After the moisture is reduced below 12%, the material is ready to be pressed into pellets or briquettes. The air flow dryer is a pre-treatment facilities always with briquette press.

ABC Machinery - Model Flalt Die Pellet Machine - Flalt Die Pellet Machine

Flat die pellet mill featured with the unique advantages of simple structure, small area coverage, competitive price and low consumption, it is a good choice for small-scale industrial production and home use. Flat die pellet mill becomes more and more popular in small biomass and feed industry.ABC Machinery - Model 5TPD cooking oil mill plant - 5TPD cooking oil mill plant

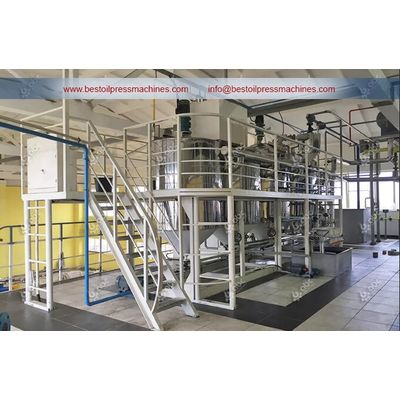

Mini Oil Mill Plant adpots YZS series screw oil expeller press to maximize the oil pressing efficiency and minimize the investment cost of cooking oil production. ABC Machinery provides a series of rapeseed oil extraction equipment like rice bran oil machine, oil production line, rosehip oil extraction machine that is neccessary for any oil mill or oil extraction plant.ABC Machinery - Model GC-MBP-2000 Sawdust Briquette Press - GC-MBP-2000 Sawdust Briquette Press

The GC-MBP-2000 sawdust briquette press designed by our company is a kind of curing molding equipment that compacts the crop straw forest cutting residue into fuel pressing block after dusting, compression, shaping and other processes. The sawdust briquette making machine has the characteristics of low power consumption, high production efficiency, long running life and low maintenance rate.Complete set of biomass briquette plant:

1. Main engine

2. Silo

3. Conveyor

4. Electric control cabinet

5. Oil cooling system

6. Accessories (according to actual contract requirements)

ABC - Stamping Briquette Plant

Mechanical Stamping Briquetting is a kind of curing process which can turn biomass materials such as crop straw, sawdust, barks, twigs and wood chips into log briquettes. Biomass log briquettes are the most promising and cost-effective energy resource for heating system. A complete briquetting plant generally includes crushing, drying, compressing, molding and packing process.

ABC Machinery - Model 2TPH biomass briquette plant - 2TPH biomass briquette plant

A complete biomass briquette plant generally includes crushing, drying, compressing, molding and packing process. The sawdust briquette machine is a kind of curing process which can turn biomass materials such as paper,crop straw, sawdust, barks and wood chips , rice husk ,coconut shell into log briquettes by wood briquette machine. Biomass log briquettes are the most promising and cost-effective energy resource for heating system.With this innovative fire briquettes machine, you are enabled to briquetting or pressing any biomass material including wood chips, sawdust etc into round shaped briquette machine of 70mm diameter or pellets of 8-30mm.

ABC Machinery - Model YZS-120 screw oil press - ABC Machinery YZS-120 screw oil press operation

1. Start the motor, start the machine, add 6%-8% moisture to the cake, pour it into the hopper, polish the press chamber, and do not feed too much, otherwise it may cause the press chamber to block and jam the soybean oil machine. Slowly and evenly, after the pressing chamber is polished and the cake is normally discharged, the raw material can be poured into the hopper.Pellet Plant

ABC Machinery - Ring Die Pellet Plant

Ring die pellet plant is the complete equipment for large pellet production. It is the ideal choice for the one who want to produce biomass pellets in a large scale for ring die pellet plant is the production line that can generate raw materials continuously. The productive process is generally wood splitting, crushing, drying, pelletizing, cooling & sieving, packing. And each step is matched with the corresponding device. For example, wood splitter, crusher/hammer mill, dryer, pellet machine, cooler, packager, etc. The yield of ring die pellet plant can reach 20t/h if you combine several ring die pellet machines. ABC Machinery will supply you with the turn-key solutions, so you don`t need to be worried about how to set up the whole large pellet plant and we will help you to set up the complete production line with the lowest investment. The equipment adopts special materials, which greatly reduces maintenance frequency, bringing you the largest profits.

ABC Machinery - Flat Die Pellet Plant

Flat die pellet plant is different from ring die pellet plant, it is a small or medium scale production line (the yield with one pellet mill is under 500kg/h, you can combine several pellet machines to improve the production) that is usually used by small or medium scale factory, farm, and so on. If you are the beginner, you can choose flat die pellet plant to start your own business for it is easy to operate and has less investment than ring die pellet plant.

Briquetting Plant

ABC Machinery - Punching Briquette Machine

Punching briquetting line that is a complete production line, refers to a series of production processes from the pretreatment of raw materials, briquetting to packaging. It involves several equipments, crusher/hammer mill, dryer, punching briquette machine, packager, etc. Punching briquette machine as a fuel briquette machine plays an important part in the production line. It can produce both fuel briquettes and pellets, which are usually used for industrial production. There are many raw materials that punching briquette line can turn into fuel briquettes or pellets, such as saw dust, peanut shell, rice husk, cotton rod, sorghum shell, twigs, branch. The end products can be used for enterprise and public institution heating or communal heating, industrial boiler, cooking, household fireplace even biomass power generation.