Advanced Integrated Technologies (AIT) products

Spot Welding Machine

Janda - Heavy Duty Rocker Arm Spot Welder

JANDA’s Rocker Arm spot welders offer great versatility for a wide variety of spot welding applications, satisfying all the requirements of HEAVY duty industrial applications.

Janda - Model SERIES 300 - Rocker Arm Spot Welder

JANDA’s SERIES 300 Rocker Arm Spot Welders offer great versatility for a wide variety of spot welding applications, satisfying all the requirements of light-medium duty industrial applications

Janda - Press Type Welder

JANDA’s High-production Press Type welders are available in 20 to 250 KVA single phase and 75 to 500 KVA three phase.

Pulse Arc Welder

Orion - Model 200i and 250i - Micro-Arc Welding

The Orion Pulse 200i and 250i have a variety of some of the most advanced micro-arc welding features available. The 200i and 250i utilize Intelligent Welding technology that streamilines the welding process by automatically adjusting settings based on metal and application. The user will have the added benefit of touch-screen navigation, multi-pulse settings for more precise welds, and high-frequency agitation for the tough jobs and metals.

Orion - Model PA230 - Pulse Arc Welder

Sunstone`s Orion PA230 is a pulse arc welder utilizing 230 joules as well as a resitance spot welder using capacitative discharge technology. The PA230 has 3 different weld modes that can be changed at the push of a button and weld energy adjusted to suit the application. This model is suited for a variety of metals and applications, even more exotic metals such as gold and finds good applications in the medical industry and laboritories, given it`s versatility.

Ultrasonic Welders

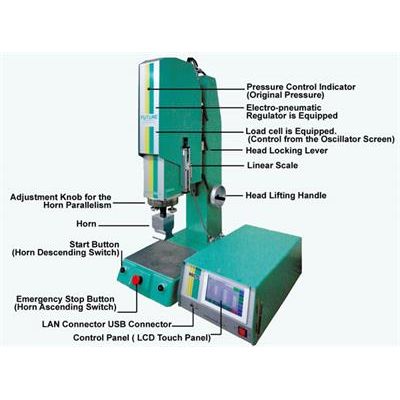

Model W5000 Series - Ultrasonic Welders

A rigid press structure for welding large items,Provides welds using super-sized horns.

Model 8,000W Series - Ultrasonic Welders

W5000 series ultrasonic plastic welders allow control of welding parameters (welding time, welding displacement, welding energy, & welding data output). A color LCD touch screen front panel provides user friendly and intuitive operation. Welding parameter data used for controlling can be output to a network environment (LAN) or saved to a USB storage device during operation. This easily accessed parameter data history is valuable for quality control. Color LCD display of main weld parameter waveforms is beneficial for better on-site management and analysis of the welding process.

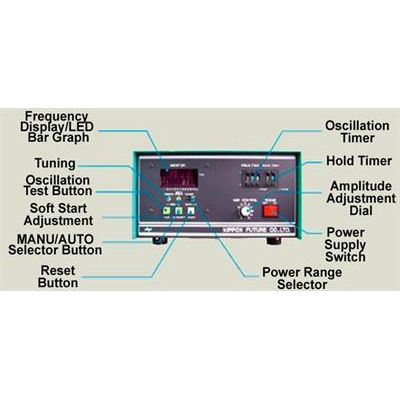

Model 3,000W Series - Ultrasonic Plastic Welder

Operation / setup iseasy. Changing horn height will not change the oscillator timing as the weld head is equipped with a pressure trigger. No adjustment required. Standard equipment on this product includes: Frequency Monitor, Amplitude Adjustment mechanism and an External Ultrasonic Output