Advanced Integrated Technologies (AIT)

- Home

- Companies

- Advanced Integrated Technologies (AIT)

- Products

- Model 8,000W Series - Ultrasonic ...

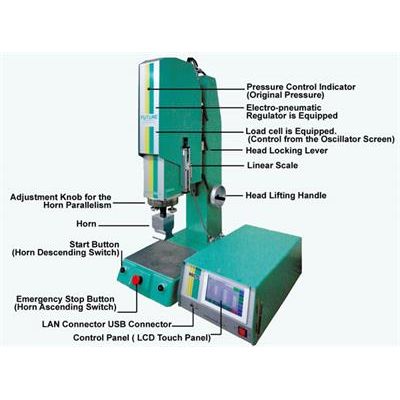

Model 8,000W Series -Ultrasonic Welders

W5000 series ultrasonic plastic welders allow control of welding parameters (welding time, welding displacement, welding energy, & welding data output). A color LCD touch screen front panel provides user friendly and intuitive operation. Welding parameter data used for controlling can be output to a network environment (LAN) or saved to a USB storage device during operation. This easily accessed parameter data history is valuable for quality control. Color LCD display of main weld parameter waveforms is beneficial for better on-site management and analysis of the welding process.

Most popular related searches

ultrasonic welder

load cell

pressure monitoring

load pressure cell

pressure cell

pressure regulator

welding air

•Welding energy control and management – Maintains welding energy constant and monitors the upper and lower limits of the weld head displacement

•Welding process control and management - Holds and monitors the melting depth (DEPTH) and finished dimensions(HEIGHT)

•Management and recording of set up & welding data – Records and timestamps each welding parameter. Supports USB storage devices and connection to a network environment (LAN).

•Control and manage welding time - Delay, Oscillation period, Retention time (cooling time)

•Display of power - Displays the peak power reached during welding

•Display and record welding waveform - Frequency, air pressure, applied current, displacement of welding head, actual applied pressure and energy can be displayed and recorded

•Other Functions

• Spherical seat parallelism adjustment

• Frequency check

• 2-step pressure

• After burst

• Load cell pressure measurement and management

• 1 μm resolution welding management

• Electro-pneumatic regulator pressure control