- Home

- Companies

- AFS Technology

- Products

AFS Technology products

Scrap Tire Handling Systems

Live Bottom Hopper

The Live Bottom Hopper allows for receiving, storage, and recovery of numerous bulk materials including: Whole Tires, TDF, Wood Chips, Wood Fuel, Mulch, Compost, RDF, Grains and Crop Residues, Other Biomass, Other bulk materials. The Live Bottom Hopper is often situated to discharge to a device that provides primary metering of the material such as a Tire Separation System for whole tires or several discharge options for Bulk Fuel.

Tire Separation

Rotary Disk Separator

The Rotary Disk Separator is designed to be at the discharge of the Live Bottom Hopper. The Separator discharges one to three tires at a time.

Refinement System

The refinement system consists of belt driven live roller conveyors in a series of turns to refine separation of tires, inspect tires and reject tires outside preset dimensional specifications. Turns in the refinement configuration will incorporate a vertical turning post to aid the tire through each corner. Also included is a tire reject bin with access door and fork truck lifting capabilities. A structural steel platform is specifically designed to support the system is provided. The platform includes handrail and one stairway access.

Precalciner Fuel Systems

Tire Skewer

AFS Technology has recently patented the Skewer Suspension Burner, which takes advantage of the donut shape of the tire to hold it in suspension for 100% fixed carbon burnout. With this method, multiple tires can be securely suspended in the high gas velocities of the riser duct or feed shelf hood for maximum NOx reduction benefit. Field testing has demonstrated feed rates exceeding 3 tons/hr for sustained periods, and possibly working over 6 tons/hr using two burners. Essentially there are two types of Tire Skewer Suspension Burners; the cantilevered and the spanning. Each is based on the calciner diameter and the method tires are loaded on the skewer rod. Large diameter calciners will normally require the cantilevered version, while smaller diameter calciners will use the spanning version.

Tire Fuel Equipment

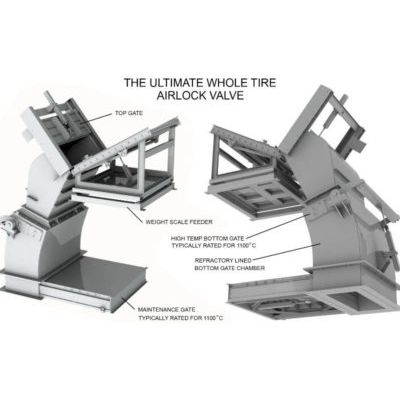

Double Gate Airlock Valves

AFS standard airlock valves are designed to introduce whole tire fuel into a combustion chamber that has a slight negative pressure. The airlock valve has two gates which create an airlock as the tires enter the chute and drop onto the feed shelf of the kiln. The most common use of these valves is for whole tires up to 48” in diameter and 17 inches wide. A high temperature maintenance gate is also provided to isolate the airlock valve during maintenance & shutdown periods.

Mid Kiln Valves

Our Mid Kiln Valves are designed to introduce Whole Tires or Bulk Fuel ~ midway along the length of a rotating kiln. At this point, temperatures are high enough and residence times long enough to ensure complete combustion of the fuel. Fuel injection occurs once every kiln rotation.

Belt Driven Live Roller Conveyors

Tire Weigh Feeder

AFS Weigh Feed Conveyors, for Whole Tire Derived Fuel, control the feed rate using the weight of each tire to determine tire injection intervals.