Alpha Cleantec AG products

Remediation (Chemical Oxidation) of Contaminated Soil

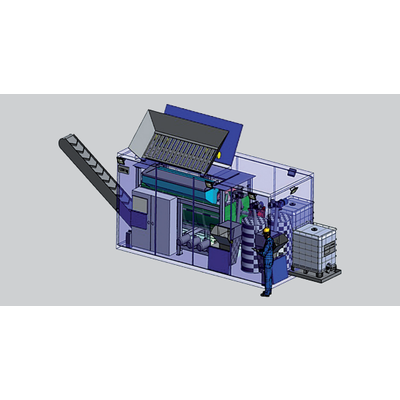

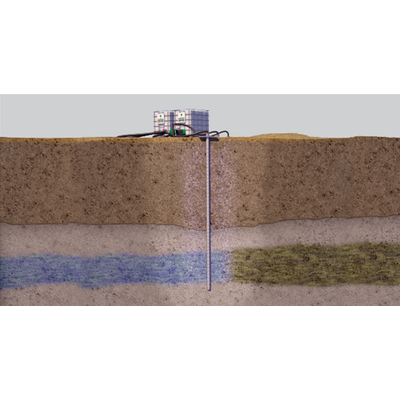

SOA and AFA – in-situ, chemical oxidation processes based on the synthetic generation of highly concentrated superoxide radical and hydroperoxyl radicals. Alpha Cleantec has developed a rapid and new solution (technology and machinery) able to decontaminate a wide range of organic pollutants (such as BTEX, TPH, PAH, CHC, PCB, herbicides, crude oil and drug leftovers) with contaminations of up to 100,000 ppm providing high conversion rates of > 90%. The technology can be applied as an on-site batch treatment process or with existing equipment for in-situ treatment. The methodology can be applied as a standalone process or as part of a soil treatment facility. Decrease carbon footprint of soil treatment market. Elimination of contaminants in minutes to hours. Treatment of a wide range of contaminants (BTEX, PAH, CHC, PCB, Herbicides) with high conversion (>90%). Decontamination without toxic by-products. Insignificant CO2 footprint. Soil, wastewater, sludge, groundwater, surfaces.Railway Track Treatment

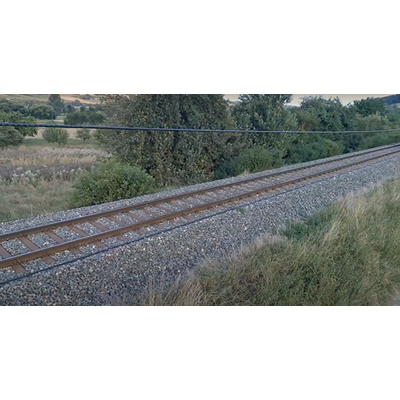

THE CHALLENGE: In-situ cleaning of railway ballast and decontamination of subsoil and groundwater from Glyphosate and toxic organic leftovers. Fast, efficient and cost-effective vegetation control with non-Glyphosate weed killer as a complementary solution. THE TECHNOLOGY: RBO – Railway Ballast Oxidation technology, is an in-situ physico-chemical technology based on the generation of superoxide radicals with surfactants and phase transfer catalysts that can simultaneously decompose organic leftovers on ballast surface, subsoil and groundwater.

Industrial Wastewater Treatment

THE CHALLENGE: Wastewater treatment is one of the most significant and impacting challenges (environmental, costs, regulatory constraints) of any industrial factory. A simple, efficient, and cost-effective solution is of great need. THE TECHNOLOGY: WWO -wastewater oxidation is an in-situ, chemical oxidation process based on the synthetic generation and stabilization of highly concentrated superoxide radical in an aqueous environment. The process is based on a new synthetic way of producing and stabilizing superoxide radical in an aqueous environment.