Alpha Cleantec AG

- Home

- Companies

- Alpha Cleantec AG

- Products

- Remediation (Chemical Oxidation) of ...

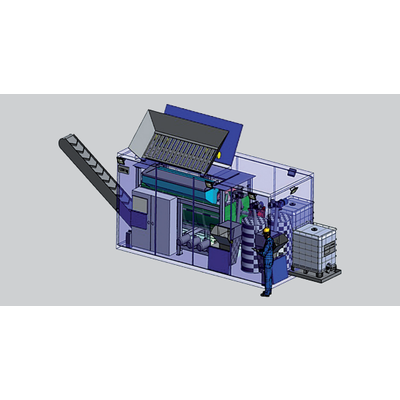

Remediation (Chemical Oxidation) of Contaminated Soil

SOA and AFA – in-situ, chemical oxidation processes based on the synthetic generation of highly concentrated superoxide radical and hydroperoxyl radicals. Alpha Cleantec has developed a rapid and new solution (technology and machinery) able to decontaminate a wide range of organic pollutants (such as BTEX, TPH, PAH, CHC, PCB, herbicides, crude oil and drug leftovers) with contaminations of up to 100,000 ppm providing high conversion rates of > 90%. The technology can be applied as an on-site batch treatment process or with existing equipment for in-situ treatment. The methodology can be applied as a standalone process or as part of a soil treatment facility. Decrease carbon footprint of soil treatment market. Elimination of contaminants in minutes to hours. Treatment of a wide range of contaminants (BTEX, PAH, CHC, PCB, Herbicides) with high conversion (>90%). Decontamination without toxic by-products. Insignificant CO2 footprint. Soil, wastewater, sludge, groundwater, surfaces.Most popular related searches

in-situ chemical oxidation

chemical oxidation

soil treatment facility

contaminated soil

in-situ treatment

soil treatment

batch treatment system

carbon dioxide footprinting

carbon footprint

organic pollution

Soil contamination by organic chemicals is a worldwide problem.

SOA and AFA – in-situ, chemical oxidation processes based on the synthetic generation of highly concentrated superoxide radical and hydroperoxyl radicals.

SUPER-OXIDATION TECHNOLOGY

Based on synthetic generation of highly concentrated superoxide radical.

SUPER-OXIDATION TECHNOLOGY

Based on catalysis by upgrading the known Fenton and Haber-Weiss reactions.

- Alpha Cleantec has developed a rapid and new solution (technology and machinery) able to decontaminate a wide range of organic pollutants (such as BTEX, TPH, PAH, CHC, PCB, herbicides, crude oil and drug leftovers) with contaminations of up to 100,000 ppm providing high conversion rates of > 90 %.

- The technology can be applied as an on-site batch treatment process or with existing equipment for in-situ treatment.

- The methodology can be applied as a standalone process or as part of a soil treatment facility.

- Decrease carbon footprint of soil treatment market.

- Granted Patents

- Elimination of contaminants in minutes to hours

- Treatment of a wide range of contaminants (BTEX, PAH, CHC, PCB, Herbicides) with high conversion (> 90%)

- Decontamination without toxic by-products

- Insignificant CO2 footprint

- Cost-effective

- Very low electricity requirement

- Treatment procedures does not avoid continued use and safe work on site

- Safe for users and environment

- Adaptable to existing equipment and process