AlphaSTAR software

Material Characterization & Qualification Solutions

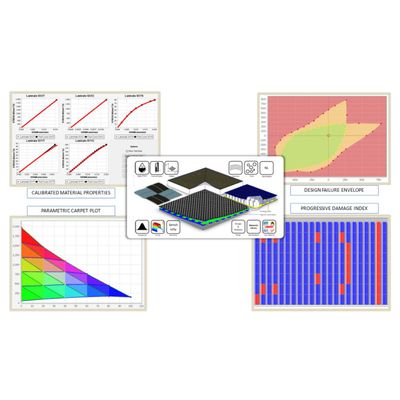

MCQ (Material Characterization & Qualification) is the material modeling tool that enables ultra-rapid design and analysis of advanced composite materials, such as continuous & discontinuous PMC, CMC and MMC. MCQ is analytically based utilizing a unit cell approach for assessing material behavior. It models all types of composite architecture, including 2D/3D woven and braided material using multi-scale physics-based micro/macro mechanics formulations. It accounts for “as built” and “as-is” states taking into consideration manufacturing defects, and effect of uncertainties in material properties and specimen geometry. MCQ output can be used as input into finite element solvers such as Abaqus, Ansys, Ls-dyna, NX-Nastran, and MSC-Nastran. Fast, powerful and an easy to use, MCQ is the solution for your material modeling needs.

GENOA Multi Scale Progressive Failure Analysis

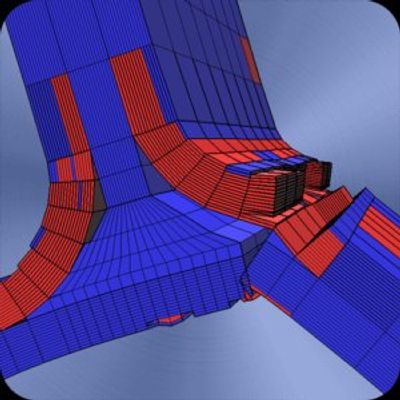

GENOA Multi Scale Progressive Failure Analysis is a tested & verified simulation software that augments traditional Finite Element solvers to predict behavior of advanced composite materials & structures subject to various loading conditions. The predictive computational technology integrates damage and fracture mechanics allowing analysts to track damage initiation and propagation until the loss of structural integrity occurs. The platform supports both virtual testing (e.g. static, fatigue, impact, allowables) and virtual manufacturing (e.g. filament winding, injection molding, 3D-Printing) and helps reduce the need for expensive physical experiments. GENOA is tightly coupled with Abaqus, Ansys, Lsdyna, NX-Nastran and MSC-Nastran.

GENOA 3DP Simulation

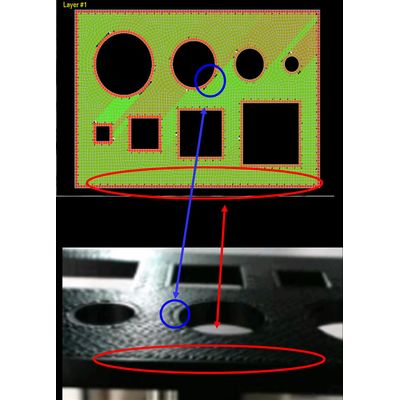

GENOA 3DP is an award wining software that offers unparalleled ability to model various additive manufacturing processes and materials across polymer and metal applications. Users can implement micro & macro voids into their process models resulting in virtual precision assembly. The end result is the ability to identify optimal build plan and parameter setting for a quality build in place of costly trial & error. The software can benefit machine operators looking for up front guidance on parameter settings, as well as CAE analysts looking for digital thermal and structural assessment of their printed parts.

Toolpath Simulator for Stratasys Grabcad Print Pro

Revolutionize your 3D printing workflow for Stratasys FDM machines with AlphaSTAR’s award-winning simulation software, now available as a plug-in for GrabCAD Print Pro. With toolpath-driven analysis, you can improve your design cycles and generate more precise, qualified builds, while also reducing print iterations. Quality assessment of toolpath and thermal process simulation are just some of the many benefits of this powerful software that will take your 3D printing to the next level.