- Home

- Companies

- AmPro Innovations

- Products

AmPro Innovations products

3D Printer

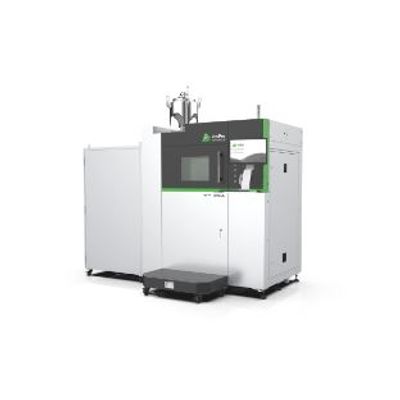

AmPro Innovations - Model SP101 SLM - 3D Metal Printer for Materials R&D and Prototyping

The SP101 SLM 3D Metal Printer by AmPro Innovations is engineered for technical applications in materials research and development, prototyping, and small parts production, making it suitable for educational purposes as well. The printer accommodates builds up to 100mm in diameter and 60mm in height, with additional build height configurations available. A hallmark of the SP101 is its removable build and powder cartridges, designed for swift turnover to maximize operational uptime. It excels in precision manufacturing, capable of producing fine tolerances with an accuracy of 0.02 mm and high density of ≥ 99%. This model is compatible with a broad range of metal powders, including nickel and titanium alloys, stainless and tool steels, and tungsten. Technically, it features a 200W fibre laser and a 2-axis scanner integrated with an F-theta lens. For ease of use, it includes a 7-inch touch screen interface powered by AmPro's proprietary printer controller software.

AmPro Innovations - Model SP160 SLM - 3D Metal Printer for Volume Production

The SP160 SLM 3D Metal Printer by AmPro Innovations is meticulously engineered for the volume production of small components across diverse production environments. This compact machine is equipped with dual 500W IPG lasers and features an open parameter library, making it ideal for highly automated manufacturing processes. The SP160 stands out with its removable build and powder cartridges, allowing for efficient handling and maintenance. It boasts precision capabilities, delivering printing accuracies of 0.02 mm with material densities of at least 99%, exemplified by applications such as printing anti scatter grids for CT scanners with extremely thin walls. The machine supports a variety of metal powders including nickel, stainless steel, tool steel, aluminium, titanium, cobalt-chrome, and tungsten alloys. Equipped with a user-friendly 7-inch touch screen and AmPro Printer Controller software utilizing the .CLI file format, the SP160 enhances operational workflow in high-demand production settings.AmPro Innovations - Model SP261 SLM - 3D Metal Printer

The SP261 SLM 3D Metal Printer is optimized for increased production rates and seamless process integration, catering to the demanding needs of metal part manufacturing. It features a sizable build volume of 250 x 250 x 300 mm, designed for creating intricate and durable components. The printer incorporates a bi-directional powder recoater and an automatic powder feeding system, enhancing efficiency during operation. Twin 500W IPG lasers combined with Scanlab 2-axis technology deliver precise and consistent results. The slide-out build chamber reduces downtime by facilitating powder and part removal, and its design allows for straightforward operator access. The machine's compatibility with a range of metal powders including titanium, aluminum, stainless steels, tool steels, cobalt chromium, and nickel alloys, highlights its versatility in handling various industrial applications.

Powder Handling

AmPro Innovations - Model G4 - Glovebox - Powder Removal for 3D Printing

AmPro Innovations' G4 Glovebox is designed for efficient powder removal in additive manufacturing processes, providing a fully inert environment to safeguard both the operator and the material properties. This system is capable of handling complex geometries with ease, thanks to its integrated inert gas blow gun and dual build rotation axes which facilitate thorough cleaning of residual powders. It supports a build volume up to a diameter of 575mm and a height of 500mm, with a maximum load capacity of 150kg, making it compatible with most major 3D printers. The design includes a quick purge cycle under five minutes, ensuring a swift transition to a clean state. The G4 Glovebox also features a full inversion capability for the build plate, enhancing the efficiency of the powder cleaning process. Its sturdy construction and large access enclosure door enable easy installation and maintenance, making it an essential tool for advanced 3D printing applications.

AmPro Innovations - Model G40 - Glovebox for Safe and Efficient Powder Removal

The G40 Glovebox provides a controlled environment for the safe and efficient removal of powder from large, complex 3D-printed parts. It features a fully inert environment with oxygen content monitoring to ensure the highest safety standards are met. Equipped with rotation functionality in two axes and an inert gas-powered blowgun, the glovebox facilitates easy removal of powder from difficult-to-reach areas and intricate geometries. Its design supports build volumes up to 900 x 900 x 1200mm and can accommodate loads up to 1800kg, making it compatible with a wide range of major 3D printers. The G40 Glovebox can be purged of contaminants in less than five minutes, maintaining efficiency and productivity in industrial settings. Additionally, its robust structure and optional vibration functionality enhance its versatility in powder handling processes.