- Home

- Companies

- AmPro Innovations

- Products

- AmPro Innovations - Model SP261 SLM - ...

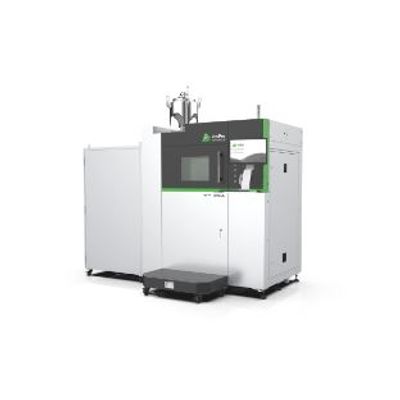

AmPro Innovations - Model SP261 SLM -3D Metal Printer

The SP261 SLM 3D Metal Printer is optimized for increased production rates and seamless process integration, catering to the demanding needs of metal part manufacturing. It features a sizable build volume of 250 x 250 x 300 mm, designed for creating intricate and durable components. The printer incorporates a bi-directional powder recoater and an automatic powder feeding system, enhancing efficiency during operation. Twin 500W IPG lasers combined with Scanlab 2-axis technology deliver precise and consistent results. The slide-out build chamber reduces downtime by facilitating powder and part removal, and its design allows for straightforward operator access. The machine's compatibility with a range of metal powders including titanium, aluminum, stainless steels, tool steels, cobalt chromium, and nickel alloys, highlights its versatility in handling various industrial applications.

Ideal for parts production with increased build rates and whole process integration.

- Simple to use, efficient printing system

- Build parts up to 250 x 250 x 300mm

- Bi-directional powder recoating

- Large capacity automatic powder feeding.

- Twin 500W IPG lasers

Slide Out Build Chamber

The SP261 build chamber is designed to decrease machine downtime caused by powder and part removal, whilst ensuring operator access for all related machine processes.

The design of the SP261 includes the ability of the build chamber to be drawn out of the machine, providing operators with essential access for powder and part removal.

General Parameters

-

250 x 250 x 300 mm (L x W x H) Build Volume

-

Slide out build chamber

-

Bi-directional re-coater

Machine Dimensions

-

2886 x 1730 x 2750 mm (L x W x H)

-

Recommended 4 x 2 x 3 m (L x W x H) Installation space

Optical Parameters

-

Twin 500W IPG lasers

-

Scanlab 2-axis

Metal Powder Compatibility

Including but not limited to:

-

Titanium Alloys

-

Aluminium Alloys

-

Stainless Steels

-

Tool Steel

-

Cobalt Chromium

-

Nickel Alloys