Apprentice

5 software found

Apprentice software

Manufacturing Execution System

Get from kickoff to first batch-run in days, not months Accelerate process design without any code. Put power in the hands of your team. With intuitive, no-code procedure and recipe authoring designed for process scientists and process engineers, your teams can configure Tempo without code. Collaboratively author recipes with teammates and experts: Tempo allows users from your organization – or even across CDMO and their customers – to author recipes together in real-time with live group-editing collaboration tools. Create intelligent procedures out-of-the-box: Users can quickly create intelligent workflows with advanced capabilities like parallel execution, branching, and enforcement logic, as well as integrate referenceable parameters, formulas, equipment, materials, and operator actions, without a single line of code.

Laboratory Execution System

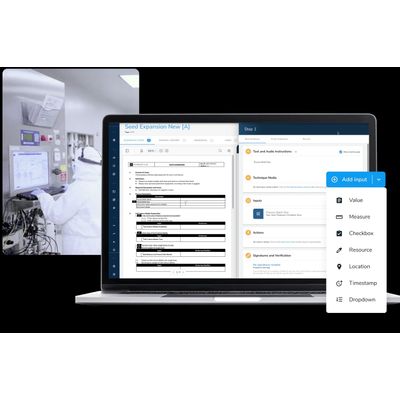

Create rich digital work instructions for better test method execution. Develop test methods without any code: Put power in the hands of your scientists. With intuitive, no-code method authoring designed for scientists, your quality team has full control to develop test methods on their own. Collaboratively author with teammates and experts: Tempo allows users from your organization to author test methods together in real-time with live group-editing collaboration tools. Produce intelligent methods out-of-the-box: Users can quickly create advanced workflows with sophisticated capabilities like parallel execution, branching, and enforcement logic as well as integrate referenceable parameters, formulas, equipment, materials, and scientist actions, without writing a single line of code. Augment test methods for better scientist execution: Any user can add augmented guidance – photos, videos, and AR overlays – to any step of a procedure.

Tandem Collaboration System

Video conferencing built for the pharma facility. Connect with colleagues on-the-go: With video conferencing that’s available on desktop, mobile, and headset devices, you can take your team with you wherever you go in your facility. Give a first-person perspective of equipment or instruments: Show collaborators a close-up view of equipment and instruments through a video camera on a wearable headset. Move around objects to troubleshoot with critical speed. Connect hands-free: Join and control a Tandem session with voice navigation to keep your hands free for your work. Compliant with pharma regulations: Tempo devices are optimized for use in all environments – the suite, cleanrooms, and while wearing PPE - are cleanable, rugged, and ATEX certified.

Workflow Execution System

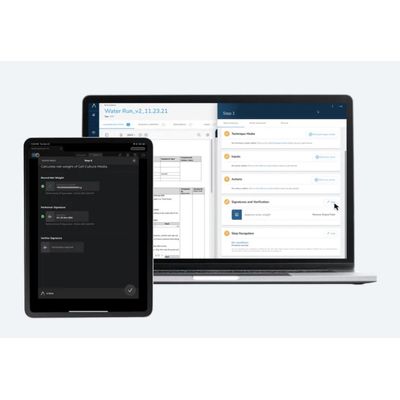

Digitally author and augment workflows for any team in your enterprise. Setup a procedure in hours - not weeks: Convert an existing paper-based procedure with a design wizard that automatically converts a PDF to digital steps, or start a new digital process from scratch. Create reusable batch and procedure templates that act as building blocks. Accelerate process design without any code: Put power in the hands of your operators. Teams can configure Tempo with intuitive, no-code procedure and recipe authoring designed for process scientists and engineers.

Collaboratively author recipes with teammates and experts: Tempo allows users from your organization – and even across CDMOs and their customers – to author recipes together in real-time with Google-docs style collaboration tools.

Resource Management System

Create accurate and reusable definitions of resources. Accurately capture your resource management structure: With customizable and reusable hierarchies and profiles, create a definition of samples, materials, equipment, locations, and more that reflects how your facility manages resources. Easily update your resource masters through our intuitive UI without code, and reflect those changes throughout the platform. Precisely understand the attributes of a given resource: Customize out-of-the-box statuses and attributes to create a precise and comprehensive picture of the readiness of resources available in your facility.