- Home

- Companies

- Apprentice

- Software

- Manufacturing Execution System

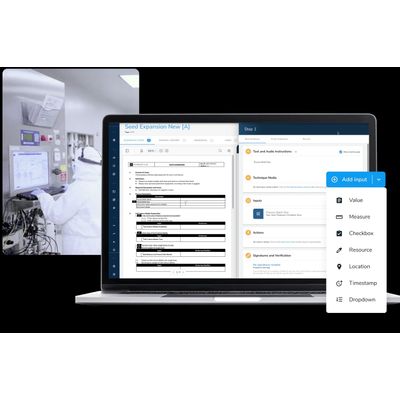

Manufacturing Execution System

Work where you are, not where your workstations are

Our native mobile app and hands-free, voice-enabled headset moves with you. Tempo is optimized for use in all environments – the suite, cleanrooms, and while wearing PPE.

Follow augmented instructions for more accurate execution

Operators can follow audio or text instructions enhanced with photo, video, and AR overlay directions that are specific to the equipment and layout in their suite to make each procedure step crystal-clear.

Reduce human error with system intelligence

Our no-code IoT integrations automatically capture data from equipment readouts in the procedure log, while programmable guardrails prevent operators from completing a step when values deviate from defined ranges and calculate formulas automatically.

Accurately capture your resource management structure

With customizable hierarchies, profiles, and statuses, create a definition of materials, equipment, and locations that reflects how your facility manages resources.

Manage material inventory in real time

Oversee the lifecycle of materials and work-in-process inventory with weigh and dispense and inventory management capabilities that update in real-time, as inventory is used inside and outside of batches.

Precisely track equipment status and use

Track the status and usage of equipment in the context of batch runs with equipment management. Use system-generated QR labels or 1d and 2d barcodes to scan-in equipment when it’s used in procedure.

Out-of-the-box quality management and batch review

Built-in conditions and exceptions provide out-of-the-box review and release by exception. A robust electronic signature system is compliant with 21 CFR Part 11. Integrate with your QMS to keep a centralized quality log.

Optimize product quality in real-time

Review exceptions as they happen. With Tempo, you can streamline batch review to immediately remedy exceptions – rather than waiting months and following a paper trail.

Get the full picture of quality with detailed data capture

Our built-in Electronic Batch Record (EBR) captures every value, action, exception, and activity of the batch run – and supports manual exceptions with videos, photos, and AR overlays.