ATLANTA Drive Systems, Inc. products

Rack & Pinion Systems

ATLANTA - Ultra-High Precision Rack & Pinion Drive Systems

These advanced Rack & Pinion Drive Systems are engineered for applications requiring ultra-precise positioning and repeatability in various industrial processes. Through innovative dual-pinion setups, these systems efficiently eliminate backlash, ensuring maintained positioning accuracy during acceleration, deceleration, and directional changes. The system configuration includes options such as split-pinion arrangements, offering fully adjustable preload settings via axial spring packs. This configuration directly integrates into High-Torque and High-Performance Servo-Worm Reducers. Alternatively, dual-pinion electrical preload systems utilize a master/slave configuration with motor controllers to remove backlash electronically. These systems, coupled with automatic lubrication, afford a robust solution for high-precision applications like traveling gantries, CNC machines, and material handling axes. With precision levels varying with rack choices, rack pitch errors are minimized, setting new standards in drive accuracy and reliability. Gearbox ratios range broadly, accommodating a vast array of load and torque demands.

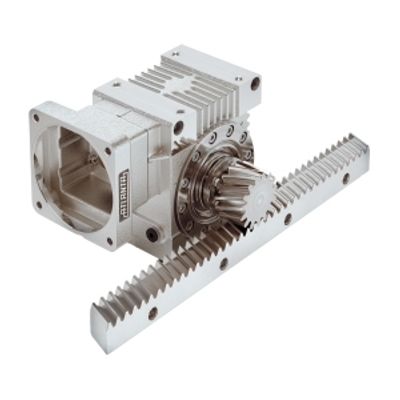

ATLANTA - High-Precision Rack and Pinion Drive Systems

The high-precision rack and pinion drive systems are engineered for applications demanding exceptional accuracy and durability. These systems incorporate precision planetary and servo-worm reducers, capable of achieving backlash levels as low as one arc-minute. The design ensures robust support through hardened and ground pinions which operate seamlessly with hardened and ground racks. Ideal for axis drives, traveling gantries, CNC routers, and robotic systems, these drives handle heavy loads and demanding duty cycles efficiently. Utilizing continuous grease lubrication, the automatic lubrication systems are recommended for maintaining gear integrity and extending operational lifetime. The systems offer various precision levels, with rack pitch errors ranging from 0.012 mm to 0.036 mm per meter. Furthermore, the reducers, available with ratios from 4.75:1 to 52:1, come in multiple configurations to suit specific application needs. For applications where eliminating backlash is critical, dual pinion setups with electronic preloading are recommended. These systems are pivotal in delivering precise and repeatable motion control in advanced industrial settings.

Gear Racks

ATLANTA - High-Precision Hardened & Ground Racks

ATLANTA's Ultra-High Precision DIN 3 and 5 Racks are designed to meet high accuracy application demands. These racks are manufactured with precision control, offering four precision levels from DIN 3 to 7 and AGMA 11 to 12+, with pitch accuracies up to 0.012 mm per 1,000 mm. Available in straight and helical versions and modules ranging from 1.5 to 12.0, they can be provided in lengths up to two meters. These racks ensure minimal pitch error across complete travel lengths, removing the need for electronic compensation in certain applications. The precision pitch and parallelism result in drives with extremely low backlash without preloading. By pairing with ATLANTA's Split-Pinions, ultra-precise zero-backlash axis drives are achievable. ATLANTA's continuous improvement has reduced total pitch errors, particularly over long racks up to 2,000 mm. Using a Rack Assembly Kit ensures accurate pitch across rack segments, enhancing precision over extensive axes.

Pinion Gears

ATLANTA - ISO 9409-1-A Flanged Pinions for Precision Drives

The newly expanded range of ISO 9409-1-A flanged pinions by ATLANTA offers considerable flexibility for machine designers. The TR flanged pinions stand out for their compact design, which significantly reduces the drive torque required. This allows the use of smaller reducers compared to traditional flanged pinions with larger pitch diameters that increase torque demands on the reducer. These pinions are designed for ease of mounting and replacement, featuring hardened and ground surfaces with a quality level of DIN 5. Available in both straight (spur) and helical-toothed versions, they come in metric modules ranging from 2.0 to 8.0. The smaller pinion diameters provide substantial benefits to rack and pinion drive systems, influencing factors such as gearbox torque, system size, ratio, linear backlash, stiffness, and resonant frequency. When paired with ATLANTA's precision gear racks, these pinions enable the creation of highly dynamic axis drives with precision and repeatability.