ATM Recyclingsystems GmbH products

Briquetting Presses - Arno Brik

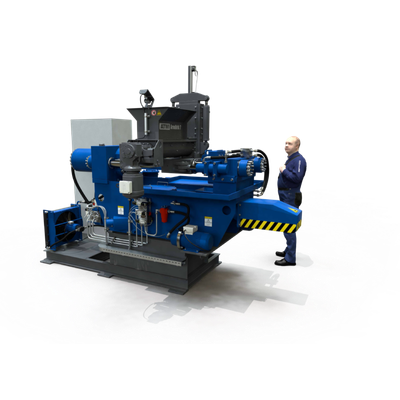

ATM Arno Brik - Model 5 - Briquetting presses

Movable tool frame: Enormous reduction of wear in the press box: The movable tool frame compensates for relative movement during the compression phase. High-density briquettes: Excellent transport and melting properties thanks to high briquette compression. 2-column technology: Maximum variability in tool loading. The columns with patented locknuts handle millions of compression cycles at full load. Compact design: Minimal space requirement due to the compact machine design. Energy efficiency: Up to 20% higher than the competition: optimized pump control technology with innovative volume flow control of the main cylinder.

ATM Arno Brik - Model 7 - Briquetting Presses

Enormous reduction of wear in the press box: The movable tool frame compensates for relative movement during the compression phase. High-density briquettes: Excellent transport and melting properties thanks to high briquette compression. 2-column technology: Maximum variability in tool unloading. The columns with patented locknuts handle millions of compression cycles at full load. Compact design: Minimal space requirement due to the compact machine design.

Briquetting Presses - Baling Presses

ATM Arno Press - Model K - Scrap Baling Presses

Arno®Press K scrap baling presses are primarily used for compacting consistent accumulations of steel sheet, brass, copper, and aluminum waste from stamping presses. The presses are available with 2 or 3 compression stages. The range includes five sizes, with types 100-2 and 150-2 compressing in two dimensions, while types 100-3 to 350-3 compact the material three-dimensionally. All components of these three-stage presses that come into contact with the scrap are lined with high-strength wear plates featuring a specialized wave-like profile. Designed as robust welded constructions, these machines are suitable for heavy-duty continuous operation. Each machine can be operated manually or automatically. With visualization of all processes, these systems can be integrated into production lines and maintained via a modem.

ATM ArnoPress - Model D - Baling Presses

The baling presses of the SPD series are available in five sizes. Types 80-2 and 100-2 compress in two dimensions, while types 100-3 to 300-3 compact the material three-dimensionally. The initial compression is performed using a cutting lid, which enables pre-compaction and the shredding of bulky parts. All components that come into contact with the scrap are lined with high-strength wear plates featuring a special trapezoidal profile. Each machine can be operated manually or automatically. Special versions with loading crane, diesel drive, remote control, or a mobile version on wheels complete the range of optional features.

Others

ATM Arno Cut - Scrap Shears

Arno®Cut Series Scrap Shears are the best choice for pre-compacting and cutting of metal plates and components, car body parts and similar light- to medium weight scrap. Even steel rails can be cut with special notch blades. The machines are available in six sizes from 4,000 to 13,000 kN shear force. All compacting chamber wear plates are made of Hardox 400 up to Hardox 500 and guarantee highest quality and a long service life. Cutting cycles are optimised by linear transducer systems in the cylinders. The need for an elaborate foundation is avoided thanks to the monobloc construction. A centralized lubrication system, various clogging indicators and fault analysis guarantee simple maintenance. Comfortable operation with two joysticks and a multifunctional display in a soundproof, airconditioned cab make the scrap shear a workplace with the highest level of safety and productivity.

Breaker

ArnoBreak - Model C - Cast Iron Breaker for Scrap Processing

Cast iron breakers can be delivered in two different sizes for the efficient processing of gear housings, engine blocks and other cast iron scrap. The ArnoBreak C 400 is used mainly for light scrap. The shear movement of the serrated breaking arm generates high breaking power producing optimal part sizes for smelting. Unlike cutting processes, the breaking process works with no tool wear.

ArnoBreak - Model R - Rail Breakers

The ArnoBreak R rail breaker was developed to process railway rails effectively and can be delivered in two variants. The stationary design permits the processing of rails of up to 120 m in length. A magazine is used for feeding the rails into the breaker. There is a mobile version for use directly on the track, which is fitted with a diesel power unit and loading rig. It can efficiently break rails of around 24 m in length into short sections measuring 300 to 1000 mm. The mobile rail breaker, which is fitted on an extendable semi-trailer, can be moved to a different location very quickly. A special notching and breaking process ensures that the rails are broken with minimum tool wear.

ATM ArnoCut - Model 400 - Semi-mobile Scrap Shear

The new semi-mobile scrap shear with baling and breaking function has been launched at the IFAT Entsorga 2010. Arnold Technology for Metal Recycling’s (ATM) slogan is the basis for new machine generations like the latest ArnoCut line. In order to process residual material into valuable secondary raw material, multi-functional plants with innovative processing and cleaning systems are needed. Waste disposal and recycling companies, successfully and effectively operating in their business sectors world-wide, can benefit from decades of experience provided by ATM.

ATM ArnoBrik - Model Series - Briquetting Presses

The ArnoBrik Series Briquetting Presses are offered with three different filling variants, according to the free flowing property of the material. An inclined feeder or a twostep feeder permit these presses to process both grinding slurry and drilling swarf. The solid welded construction design with two or three columns means that the machines can also be used for heavy continuous operation. Each machine can be operated manually or automatically.

Single Shaft Shredder

Arno Shred - Model SSE - Single Shaft Shredder

Specially designed for metals. All surfaces are covered with high resistance Hardox wear plates. Knifes and screens with different geometrical forms and in different materials are available. The innovating feature is the tramp metal discharge opening. All lump parts are ejected during the shredding process to protect the tool and increase it‘s lifetime. Additionally a friction clutch protects the drive mechanism against overload. Thereby the ArnoShred resists extreme conditions on scrap yards.