Aztech products

Crushers

Aztech - Mobile Crushers for Versatile Aggregate Processing

Aztech's mobile crushers present a comprehensive solution for quick aggregate processing and transport. These crushers reduce costs in the material crushing process and operate autonomously, important when working in remote areas without stable power sources. The compact machinery design ensures seamless transportation to various locations. Equipped with its drive system, the models eliminate the need for an electrical connection. Their primary use revolves around recycling construction rubble, glass movement, and other materials. Mobile crushers come in four main types: jaw, cone, impact, and roller crushers, each catering to different crushing needs. Jaw crushers handle primary and secondary material processing with low to medium capacity, while cone crushers refine fine materials. Roller crushers, on the other hand, are meant for soft materials, serving medium to fine crushing needs. Aztech's offering includes electrical, diesel, or hydraulic drives, and supports essential components like loading hoppers and conveyors, tailored to specific customer requirements.

Aztech - Hammer Crushers for Crushing Medium and Fine-Grained Material

The hammer crusher is engineered to efficiently crush medium and fine-grained materials of varied hardness, such as sandstone and basalt, as well as recycled waste material like aluminum and electronic equipment. Central to its operation is a rotor with assembled hammers that initiate impact by striking falling fragments, altering their trajectory. This method maximizes collision force with transverse beam plates, promoting further fragmentation through mutual collisions. It is widely used in the mining industry and aggregate mines for stone crushing, and is equally critical for recycling applications, such as demolition work and scrapyards. Horizontal models feature a transverse grate for precise control of output material fractions, while vertical models can crush materials to below 5 mm, accommodating higher moisture levels. Made from durable manganese steel, these machines are designed for longevity and efficient performance.

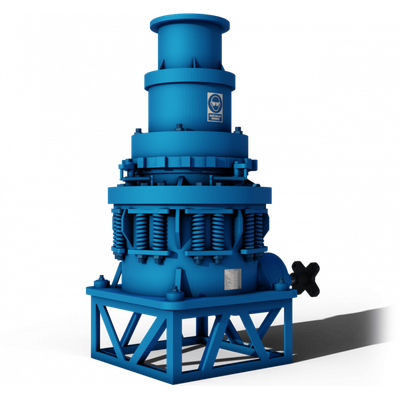

Aztech - Cone Crusher for Aggregate Production

The cone crusher is designed for processing second- and third-grade materials like quartz, granite, basalt, gravel, dolomite, and stone. It provides precise crushing into individual fractions with an excellent cubic area due to its optimal space geometry. The machine's maximum feed size capability reaches up to 300 mm, producing a finished product grain size between 3 mm to 60 mm. Its significant advantages include a high reduction ratio, low wear and tear, and stable operation that ensures failure-free usage. The crusher is built with high-grade, hardened steel, and all cones are resin-cast to prolong subassembly lifespan. Featuring both mechanical and hydraulic cone adjustments, it offers flexibility in various setups and also includes an option for hydraulic cone lifting to manage emergencies. Ideally used for road and railway infrastructure projects and quarrying, it meets stringent requirements for the production of aggregates and grit while not suitable for materials with high moisture content.

Others

Aztech - Industrial Screening Machines for Material Separation

Aztech manufactures screening machines designed to effectively sort materials into various fractions, catering to industries such as mining, construction, and recycling. These machines operate using high-frequency vibrators or rotational sieves to efficiently handle aggregates, soils, and loose materials, adaptable to specific requirements and material characteristics. The machines integrate seamlessly with crushers, conveyors, and hoppers, forming crucial components of production lines. Available in both one-deck and multi-deck configurations, they provide versatility in achieving precise material distributions, and can utilize perforated metal or woven mesh sieves. Drum screening variants are also offered for handling high-moisture materials like peat and clay. Choosing the correct machine involves considering material type, moisture level, and granulation, along with operational factors such as electric versus combustion engines for power efficiency and reliability.