- Feeding

- Pre-screening

- Crushing

- Screening & Sizing

- Washing & Classifying

- Crushing Machines - Feeders

- Crushing Machines - Grizzlies

- Crushing Machines - Mills

- Crushing Machines - Crushers

- Crushing Machines - Screens

- Crushing Machines - Belt Conveyors

- Crushing Machines - Dewatering Reclaimers

- Crushing Machines - Washing Barrels

- Crushing Machines - Fines Recovery Machines

- Crushing Machines - Washing Screens

- Mobile Units

- Recycling Machines

- Decanter Centrifuges

- Waste Treatment Plants

- Washing and Classifying

Baioni Crushing Plants Spa products

Feeding

Baioni - Vibrating Grizzly Feeders for Primary Crushers

AVC series vibrating grizzly feeders by Baioni are designed to efficiently feed primary crushers, especially when dealing with a mix of large size materials and high percentages of fines. These feeders are ideal for dry material or those with minimal moisture. The feeder consists of a robust rectangular steel casing, with the initial portion lined with heavy wear plates for durability, while the latter part is equipped with grid bars to prevent clogging and facilitate the pre-screening process. The top screen deck features bars that assist in removing fine material and soil, preventing overfeeding of downstream crushers. The feeder's vibrating frame is supported by helical springs, providing stability, while oscillations are driven by a unit located beneath the casing. The amplitude of oscillations, and hence the output, can be finely tuned to meet varying operational requirements.Pre-screening

Baioni - Grizzly Wobbler Feeder for Pre-Screening

The GD Grizzly Wobbler Feeder series by Baioni serves as an effective solution for pre-screening and cleaning sticky, wet materials with high clay and moisture content. This heavy-duty piece of equipment is engineered with exclusive non-clogging, self-cleaning elliptical bars and a robust frame. It comprises roller-holder shafts affixed with grease-lubricated bearings and interchangeable armors, facilitating maintenance and durability. Driven by an electric motor and a reduction gear unit, the system uses chains lubricated with oil to transmit power, ensuring seamless operation. Grooved rollers positioned oppositely create grid openings for effective material passage, and their unique shape induces a wave motion that optimizes the material's cleaning process. This wave action also prescreens the material, preparing it adequately for subsequent crushing stages. The GD series is recognized for its unique conceptual design that ensures product cleanliness and efficiency.Crushing

Baioni - Primary Jaw Crushers for Quarrying and Mining

The BP series primary jaw crushers, developed by Baioni, are tailored to meet the versatile demands of the quarrying, mining, and construction industries. Engineered for robustness and efficiency, these machines offer an excellent reduction ratio and high production rates, capable of processing a wide range of material types and sizes. A focus on reliable performance ensures the handling of both hard and abrasive materials with minimal energy and maintenance costs. Additionally, the expansion to include the BP-B Series caters to mobile applications, broadening their utility in dynamic environments. The construction of these crushers emphasizes precision engineering and specialized manufacturing processes, such as special welding and heat treatments, executed in Baioni's state-of-the-art facility. This expertise ensures that each crusher performs consistently, meeting the latest global trends and technological advancements.Screening & Sizing

Baioni - Inclined Vibrating Screens for Aggregate Sizing and Washing

Inclined vibrating screens by Baioni display a robust and compact design that ensures reliable performance for sizing and washing aggregates. These screens, available in V (one shaft) and VV (double shaft) series, are versatile for both fine and coarse classification across diverse productions. They feature a screen deck casing supported by springs and are equipped with a rotating shaft driven by a patented system. This system utilizes mass displacement to generate a variable eccentric, which facilitates controlled start-up and stopping phases without unwanted vibrations. The screens allow for exact vibration intensity regulation and incorporate an automatic belt tensioning system for optimized operation. Their high efficiency makes them suitable for a wide range of materials, enhancing aggregate quality during screening. Moreover, a washing system with spray sprinklers can be added to facilitate comprehensive aggregate processing.

Washing & Classifying

Baioni - Counterflow Washing Trommel for Material Washing

The Baioni ST counterflow washing trommel is engineered to meticulously wash coarse materials, effectively removing clay contaminants and various impurities from hard rock, gravel, and ore. This advanced machine features a robust cylindrical drum that rotates counter to the water flow, facilitated by a motor unit with a planetary reducer. Constructed with thick metal sheets and integrated wear-resistant materials, its internal design incorporates paddle blades and draining buckets mounted on durable steel skids tailored for specific operational requirements. As material progresses through different washing stages inside the drum, the system's persistent lifting and dropping actions, coupled with water, ensure thorough cleaning by abrading and scrubbing contaminants. The machine is adaptable with optional cylinders to accommodate diverse particle size fractions. A draining screen is available to dehydrate any organic fractions present in the flow, enhancing the cleaning efficiency.

Crushing Machines - Feeders

Reciprocating Feeder

Push-pull feeders, mod. ACP, are used for primary feedings of gravelly alluvial or mountain quarry material even if large size are involved. These sturdy constructed machines are intended for heavy duty use. They are essentially composed of a frame on which the feeding carriege is supported by means of steel wheels, which alternatively slides backwards and forwards causing the material to move forward. The alternative strake of the carriage is adjustable and given by a connecting rod-crank system driven by a motor-reducer unit.

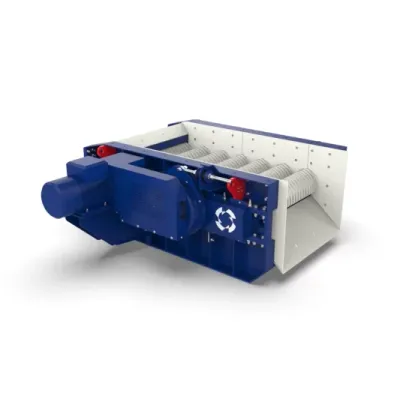

Vibrating Grizzly Feeder

Vibrating grizzly feeders, mod. AVC, are used in primary rock quarry installations where the material is of large dimension mixed with a high percentage of fine parts. The machine is particularly suitable for dry materials or in any case with negligible percentages of moisture. Mainly made up of a rectangular casing, of which the bottom is sealed, for about half of its length, by thick wearing plates, while in the remaining part some bars are mounted forming a grizzly that allows to select the material removing earth and fine parts which otherwise could overfeed the crushing machine. The support of the vibrating frame is realized on helical springs. A vibrating unit placed under the casing gives the oscillations to the machine. The amplitude of the oscillations, therefore the capacity, can be adjusted.

Apron Feeder

Apron feeders, mod. AP, are sturdy and reliable machines designed to feed big primary crushers with rocky, as well as big sized material. Mainly made up of a carrying frame and an articulated conveyor consisting of sturdy aprons. The advancement of the articulated conveyor, or track, ensures that even the biggest blocks are introduced to the crusher in a correct oriented manner. Transmission, sliding rollers, pins and aprons are largely oversized to withstand the strains and impacts of the heavy lumps discharged in the hopper. The transmission, by means of motor and gearbox enables to obtain the desired feed quality during the work without stopping the machine.

Vibrating Feeders

Vibrating feeders, mod. AV, are used for secondary feeding of gravely alluvial or pre-crushed material. Mainly made up of a plate chute hung over the fixed casing by ant vibrating rubbers and moved by two eccentric motor-vibrators. The continuous feeding and the constant capacity allow the machine that follows to work always at full rating. The feeding quantity can be adjusted by a circular sector placed on the discharge mouth or acting on the eccentric masses of the motor-vibrators.

Constrained Vibrating Feeder

Constrained vibrating feeders, mod. AW, are used for secondary and sometimes, primary feeding of gravely alluvial or pre-crushed material. They are mainly made of a fixed frame and mobile carriage supported by four arms with articulated joints provided with special rubbers that do not need any maintenance. The carriage reciprocating movement, which causes the material slide, is given by a rod-crank system. Continuous feeding and adjustable capacity allow the machine that follows to work always at steady rating.