Barge Master products

Barge Master - Motion Compensated Gangway for Offshore Access

The Barge Master Gangway is a sophisticated motion-compensated system designed to facilitate safe and efficient transfer of personnel and cargo to and from offshore structures, regardless of challenging weather conditions. Offering horizontal access for personnel and remote-controlled trolleys up to 800 kg, it features a lifting capacity of 1,000 kg. Developed in collaboration with Van Halteren Technologies, it incorporates redundancy in critical components like motion reference units to ensure maximum reliability. Its active motion compensation capability can handle vessel motions in high waves reaching up to 3.5 meters. The gangway’s modular design allows for fitting onto various pedestals, enabling adaptation to different landing heights without needing structural modification. Certified by DNV-GL, it's built for high performance, with anti-slip technology and single operator functionality. The system is also configured with unique features like a tip ladder to enhance operational range, making Barge Master's gangway a versatile solution for dynamic maritime environments.Barge Master - Motion Compensated Gangway for Offshore Operations

The Barge Master's Next Generation Motion Compensated Gangway facilitates continuous, secure access to offshore structures, ensuring the safe transfer of crew and cargo even in challenging weather conditions. The gangway accommodates a horizontal access for both personnel and trolleys up to 800 kg, with a generous lifting capacity of 1,000 kg. Its standout feature is the active motion compensation, which mitigates vessel motion up to significant wave heights of 3.5 meters, allowing flexible placement without modifying landing areas. Engineered with a modular design, this gangway features redundant critical components and technology to eliminate slip risks. The configuration includes a height adjustable pedestal with an elevator, adaptable for variable heights and equipped to maintain workflow continuity. Developed alongside Van Halteren Technologies, and incorporating Bosch Rexroth's controls expertise, it represents a robust solution for global offshore accessibility, certified by DNV-GL standards. The system is both operationally versatile and energy-efficient, highlighting its practical integration into various offshore projects.

Barge Master - Model BM-T700 - Multi-purpose Motion Compensated Platform

The Barge Master Motion Compensated Gangway is engineered to provide continuous and reliable access to offshore facilities regardless of environmental conditions. This advanced gangway system features active motion compensation, allowing it to accommodate vessel movements in wave heights up to 3.5 meters, ensuring safe transfer of personnel and equipment. Its modular design enables customization for various offshore operations, incorporating a height-adjustable pedestal with integrated elevator to maintain uninterrupted workflows. The gangway supports cargo trolleys up to 800 kg and includes a lifting capacity of 1000 kg. It boasts triple redundancy in critical components such as motion reference units, adhering to a 'fail operational' philosophy for maximal uptime. Collaboration with Van Halteren Technologies and Bosch Rexroth ensures the integration of top-tier motion control and drive systems, while its DNV-GL certification guarantees adherence to the highest industry standards. Barge Master provides tailored workability analyses and operator training to optimize the gangway’s deployment, making it a versatile asset for the offshore industry.

Barge Master - Model BM-T40 - Motion Compensated Crane

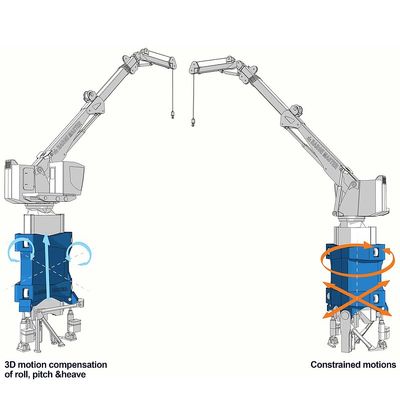

The BM-T40 Motion Compensated Crane by Barge Master is engineered for enhanced offshore operations, providing controlled lifting capabilities in challenging sea conditions. This crane significantly extends workability, particularly in areas like the North Sea, from 180 to 330 days by compensating for vessel motion at its base, ensuring stability of the operator cabin and the load. With a compact design, it can lift up to 32 meters above sea level, handling loads of 5 to 15 metric tonnes at varying reaches. Certified for manriding, the crane is suitable for transferring personnel safely and managing typical loads such as hoses, tools, and turbine parts. Its cutting-edge motion compensation technology involves hydraulic cylinders that counteract heave, roll, and pitch motions, controlled via motion reference units for precision. The system's versatility allows integration into new builds or retrofitting, making it an adaptable solution for maintenance and platform supply vessels.