- Home

- Companies

- Bearings Plus, Inc.

- Products

Bearings Plus, Inc. products

Fluid Film Bearings

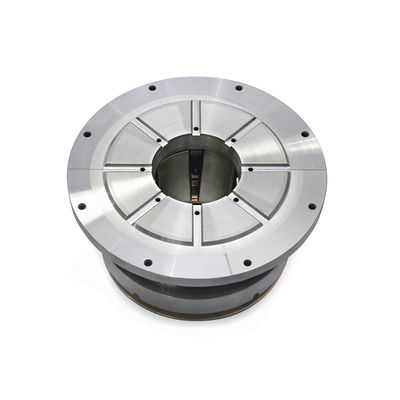

Integral Squeeze Film Damper

Squeeze film dampers are used to shift critical speeds and/or to increase the dynamic stability of the rotor/bearing system. One of the key features of a squeeze film damper is the introduction of support flexibility and damping in the bearing/support structure. This translates to lower transmitted forces and longer bearing life, particularly for machinery designed to operate at super critical speeds. Our patented, integral centering spring squeeze film dampers provide an accurate and simple approach to new and retrofit installations requiring squeeze film bearings.

Thrust Bearings

Bearings Plus offers a variety of thrust bearings, including fixed profile, self equalizing, ball and socket, rocker back and thrust plates. The design is determined by the parameters each application, depending on load capacity, speed, temperature requirements and more. Thrust bearings are uniquely engineered to reduce power loss, oil flow and temperature to ensure reliability and efficiency.

Journal Bearings

Bearings Plus journal (radial) bearings are designed to specific operating conditions for optimum performance. With fixed profile and tilt pad designs, including the compact Flexure Pivot® tilt pad journal bearing, Bearings Plus can replace or upgrade original bearings to improve the stability, reliability and service life of your rotating equipment. Combination journal/thrust bearings are available when applications have limited axial space.

Damper Seals

Hole Pattern Seals

Hole pattern seals were developed in efforts to simplify the manufacturing process from honeycomb seals. Hole pattern seals are usually manufactured from aluminum so that in the event of intermittent rotor-stator interaction, minimal damage is sustained by the rotor.Honeycomb Seals

Honeycomb seals were initially used in the aerospace industry in air-breathing gas turbine engines as abradable stator components for high-pressure turbine stages. Later, honeycomb seals were used in cryogenic rocket engine turbopumps as a damper seal at the balance piston location. Eventually this technology was adopted by the industrial market, which primarily focused on applications in high-pressure centrifugal compressors.

Fluid Film Bearings - Fixed Profile Bearings

Sleeve Bearings

Sleeve bearings are a simple and economic design with wide application in rotating machinery. These fixed geometry bearings come in several configurations to handle varying application needs for load capacity, rotating load, stiffness, damping, and rotordynamic stability (resistance to whirl). The addition of grooves can reduce destabilizing effects due to fluid rotation, while alterations to the circular geometry provide additional stability gains. Design variables to optimize performance include lobe geometry, number of lobes, bearing material, and lubrication. Lubrication may be pressure fed or self-lubrication, the latter typically with an oil ring.

Thrust Plates

For applications with low thrust loads, limited space and negligible misalignment, Bearings Plus designs and supplies thrust plates with simple or compound taper land faces. Depending on size and predicted bearing temperatures under the designed load and oil viscosity, thrust plate bearing materials can include babbitt, copper, bronze and polymer.

Fluid Film Bearings - Tilt Pad Bearings

Flexure Pivot - Tilt Pad Journal Bearings

Tilt pad journal bearings provide an inherently stable design for rotating machinery. Bearings Plus provides several pad pivot types and geometries to increase load capacity, accommodate misalignment and optimize dynamic performance of the machine. Two of the most common tilt pad designs are rocker back pads and ball and socket pads. Rocker back tilt pads use a line contact to allow the pad to tilt, while ball and socket pads have a spherical surface contact. In both instances, pads are retained in a shell (or housing) and held in place by end plates.

Flexure Pivot - Tilt Pad Thrust Bearings

Flexure Pivot tilt pad thrust bearings reduce power loss and extend bearing life over a wide range of speeds, loads and temperatures. Ideal for retrofit due to their space-saving design, these patented fluid film bearings increase load capacity, accommodate misalignment and reduce pivot wear.