- Home

- Companies

- BHR Group Limited

- Services

BHR Group Limited services

Expert-Led Engineering Consultancy Advice Services

Our experts understand fluid behaviour, mixing and containment. Using their knowledge, experience and in-house tools, they can quickly understand and quantify your challenges, providing impartial, expert advice. We can provide services including concept evaluation, design studies, technical reviews and on-site troubleshooting.

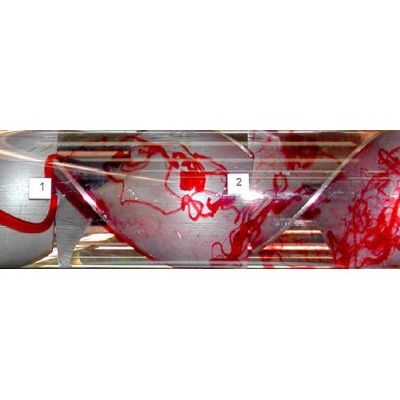

Fluid Mixing Industrial Research Service

Our extensive fluid mixing expertise is underpinned by market-leading, long running industrial research consortia. We support product development and process derisking from laboratory to production across a wide range of from semi-batch polymerisation to gas liquid optimisation.

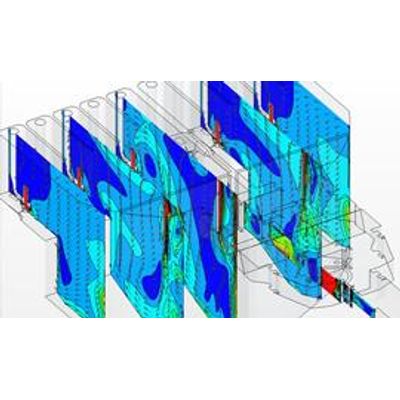

Numerical Modelling and Simulation Services

Our fluid engineering experts apply commercial computational fluid dynamics (CFD), finite element analysis (FEA), and pipe network analysis codes to address real industrial challenges. This technical capability is combined with our wealth of fluid flow knowledge to enhance these codes with bespoke numerical solutions.

Abrasive Direct Injection Abrasive Jetting Service

DIAJET (Direct Injection Abrasive Jetting) is a cold-cutting technique that provides powerful and accurate cutting and cleaning in hazardous environments. Each DIAJET system is custom designed for the client application. We provide a full, end to end service: from system design, through factory acceptance, to on site proving, operation and maintenance support.

Design and Engineering Services

Working with you, we support design development and engineering improvements utilising a range of tools, from desk studies and mathematical models to scaled models of complex structures for physical testing.

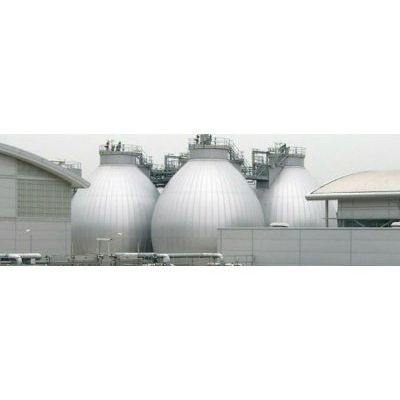

Water & Wastewater Treatment Services

At Framatome BHR, we have a strong track record of working with water and wastewater contractors and operators. We specialise in fluid engineering, using tools such as physical and computational modelling integrated with process engineering know-how. This means that our team has the right blend of specialist knowledge and practical ability to advise on both the complex hydraulic and chemical processes that are vital for safely and effectively managing the water treatment cycle.

Cooldown Testing Service

With the growing need for deep water exploration and production and future plans for deep water wells, flow assurance of pipelines and fluids is becoming a higher priority. Subsea pipelines and components need to be thermally insulated to allow the hot fluids produced at depth to retain their heat during transport, in order to prevent the formation of hydrates or waxes. Also, as wells get deeper, thermal insulation not only has to maintainin the temperatures within the pipelines, but also has to perform mechanically, in order to resist the huge pressures associated with the

depth of water above.