- Home

- Companies

- BHR Group Limited

- Services

- Cooldown Testing Service

Cooldown Testing Service

With the growing need for deep water exploration and production and future plans for deep water wells, flow assurance of pipelines and fluids is becoming a higher priority. Subsea pipelines and components need to be thermally insulated to allow the hot fluids produced at depth to retain their heat during transport, in order to prevent the formation of hydrates or waxes. Also, as wells get deeper, thermal insulation not only has to maintainin the temperatures within the pipelines, but also has to perform mechanically, in order to resist the huge pressures associated with the

depth of water above.

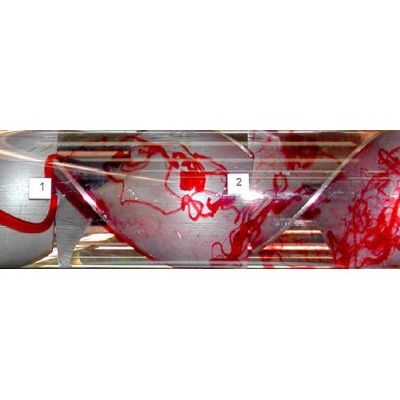

Framatome BHR offers a thermal cool down testing and Overall Heat Transfer Coefficient (OHTC) determination service where the test piece can be heated internally with either air or water. Additionally, the test piece can be placed in a cold water system with temperatures matching those observed on the sea bed.

We can test straight pipe sections of 12 -15m which means that generally, test pieces can be close to full scale. For straight pipeline sections, a modular tank system is used to construct the cold water tank to the required length. Other components, such as riser assemblies can also be tested. For other assemblies, cold water tanks can be obtained up to 10 - 12m in diameter and 4m deep. Our large, high-ceiling laboratory is capable of handling very large tanks if required.