- Home

- Companies

- Binder Co AG

- Products

Binder Co AG products

Crushing

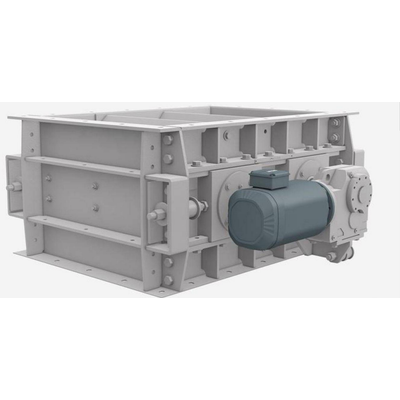

Binder - Double Roll Crusher

An optimum grain size of 10 to 50 mm is crucial for sensor-based sorting of cullet since a higher content of fines (0-10 mm) would have an unfavourable effect on sorting performance. In the form of the double roll crusher, Binder+Co has created the ideal prerequisite for the subsequent sorting of waste glass.

Screening

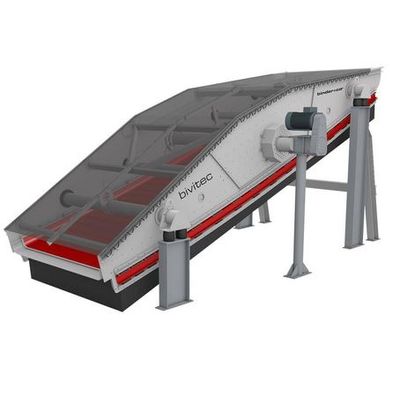

Binder - Model BIVITEC e+ - Flip Flow Vibratory Screen

BIVITEC e+ big on effect, small on consumption. The latest flip-flow screen scores with low dynamic loads, compact design and efficient screening performance even with feed material that is difficult to screen.

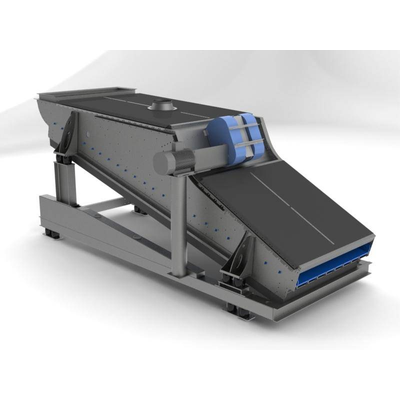

Binder - Model BIVITEC - Flip Flow Screen

The BIVITEC flip flow screen comes into its own when conventional screening technology starts to be inefficient and uneconomical. Particularly challenging tasks are solved in a simple and efficient way. The BIVITEC flip flow screen ensures selective screening of bulk materials which are difficult to screen.

Binder - Circular Vibrating Screens

The Binder+Co circular vibrating screens are typical vibrating screens. They work according to the ejection principle and carry out a circular movement. Speed and amplitude of the vibration can be adjusted according to screening task. The adjustable unbalanced masses ensure flexibility.

Binder - Linear Vibrating Screen

Linear vibrating screens from Binder+Co are a type of vibrating screen. They work according to the ejection principle and move in a linear way. The special feature of this type of screen, apart from its adjustable unbalanced masses, is the flexibility of its angles of inclination. Long vibrating screens allow for several different cut points on one screen deck.

Binder - Resonance Screens

A resonance screen is guided by suspension arms and works on the ejection principle. The eccentric drive mobilises two equal mass beams mounted in rubber sleeves which move linearly. The connecting rods of the drive system are arranged on elastic mainsprings which supply the vibration system with as much energy as is necessary. Additional positive price effects result from the lightweight substructure, low construction height and low energy consumption.

Wet Processing - Dewatering and Classifying

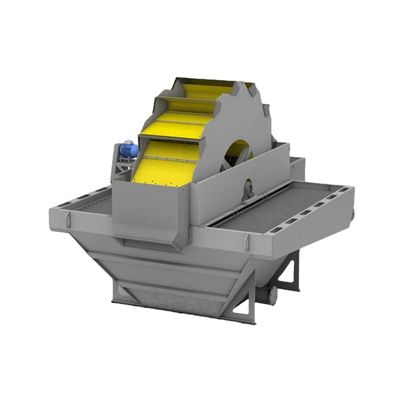

Binder - Model SANDEXX - Double Sand Trap Machine

Sand production in a Binder+Co SANDEXX double sand trap is efficient and energy-saving. Efficient because cleaning and dewatering are carried out in one operation, utilising a large pool area and gravity sedimentation. In addition to the low operating costs, the double sand trap from Binder+Co convinces with exceptionally low maintenance costs. The SANDEXX sand trap reliably dewaters and cleans sand mixtures over a wide range (quantity and composition). An optional flap in the discharge chute of the fine sand wheel allows the fine sand product to be mixed with the coarse fraction as desired. A robust design and long service life characterise this machine.

Binder - Model SANDEXX - Scoop Wheel Machine

Sand and gravel cleaning in the Binder+Co SANDEXX scoop wheel is efficient and energy-saving. Efficient because cleaning and dewatering take place in a single operation. In addition to the relatively low operating costs, the Binder+Co scoop wheel impresses with exceptionally low maintenance costs. The SANDEXX scoop wheel reliably dewaters and cleans sand and gravel mixes in a wide range (quantity and composition). A robust design and long service life characterise this machine.

Binder - Screw Classifiers

Screw classifiers or dewatering screws are used for simultaneous cleaning and dewatering of sand from upstream, brewed screening machines or for dewatering of cycloned sands. The deslurried coarse sand product is conveyed by the screw against gravity and discharged well dewatered at the upper end of the trough. The fine slurry overflowing at the lower end of the trough contains the majority of the water as well as the fines content of the sand.