Binder Energietechnik GmbH products

Transport Systems

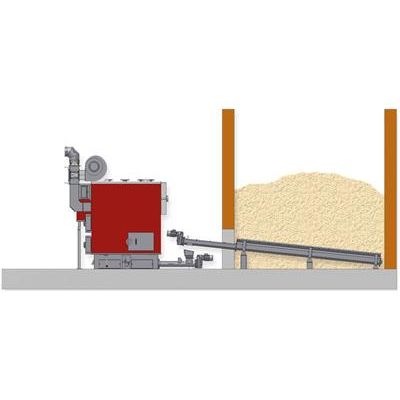

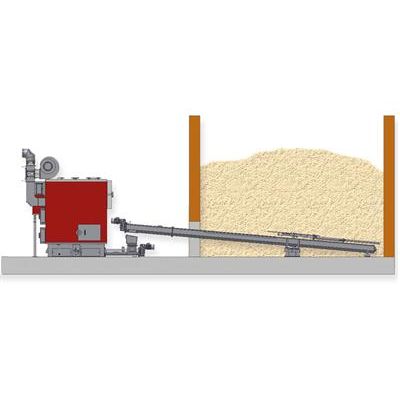

Binder - Transport Augers

BINDER offers Transport Augers in different variants. The transport auger is the part of the boiler that takes the fuel of a discharge unit and transports it towards the boiler. It consists of a screw conveyor, which is carried in a steel duct. At the end of the auger, the ejection opening, which ensures the transition to other transport units is located at the bottom. A clog detection sensor is placed over the ejection opening, which switches off the motor in the event of a blockage. The drive of the Auger is made with an gear engine and an angular gear. The steel auger duct is covered with screwed covers for easy access. The screw trough is fully welded to the steel shaft or the Steel sleeve shaft.

Binder - Direct Hydraulic Feeding Unit

Usually the Direct Hydraulic Infeed is used to transport coarse material into the combustion chamber. The QFE is mostly used in combination with an walking floor. A level sensor constantly monitors the level of material in the QFE. A hydraulically driven pusher with multiple carriers transports the material through a wall opening in the combustion unit. The required anti burnback protection is ensured by the tightly sealed cutting edges, as well as through an automatic fire extinguishing system and a battery backed up hydraulic unit which closes the pusher in case of power loss.

Extraction Systems

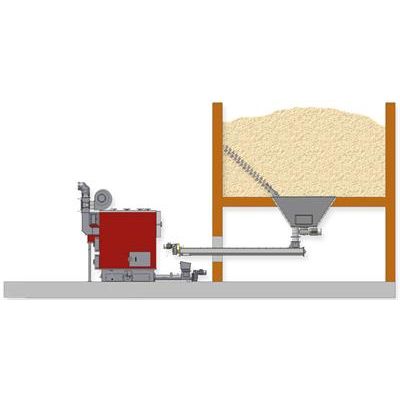

Binder - Pellet Extract Auger

Auger with adjustable pressure relief cover for transport of pellets out of a rectangular room with or without slanted floor. Depending on the fuel store size with or without universal joint.

Binder - Sweep Arm Agitator

The sweep-arm agitator is a load depending helical cutter. The substantial sweep-arm is independently powered from the auger and operates depending on the amount of fuel inside the fuel store, with variable diameters.

Binder - Tapered Sweep Auger

Free wheeling spiked auger for fuel extraction out of silos accessible from below.