Binsfeld Engineering Inc products

TorqueTrak - Temporary Measurement

Binsfeld TorqueTrak - Wireless Torque Sensor for Rotary Torque Measurement

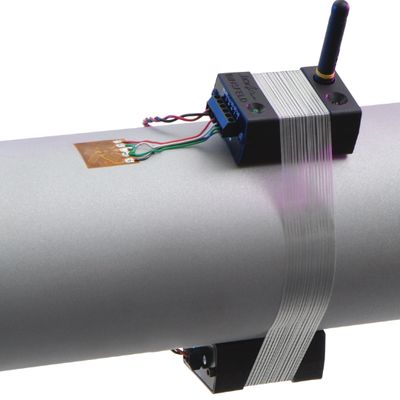

Measuring live torque in real-time is easier than ever with the TorqueTrak 10K telemetry system. Convert virtually any drive shaft into a rotating torque sensor by simply mounting the wireless torque transmitter, battery and a torque-sensitive strain gage to the shaft. Use the infrared remote control to adjust transmitter gain, activate the remote shunt calibration or switch the transmitter to standby power mode. The multi-line LCD receiver display and keypad make system adjustments straightforward. Low power consumption in the rugged transmitter allows longer battery life while sophisticated electronics assure accurate and reliable torque data output.

Binsfeld TorqueTrak - Low Profile Torque Sensor System

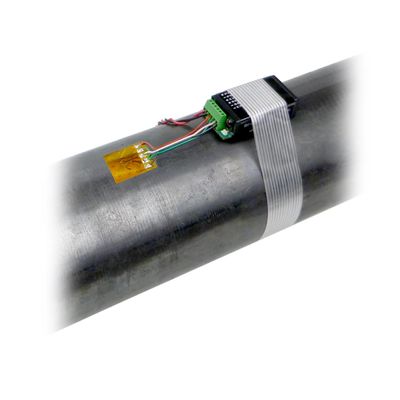

Measuring live torque in real time is easier than ever with the TorqueTrak 10K-LP (Low Profile) telemetry system. Convert virtually any drive shaft into a rotating torque sensor by simply mounting the wireless torque transmitter, battery and a torque sensitive strain gage to the shaft. At only 0.70 inches tall, the TorqueTrak 10K-LP is ideal for applications with very low radial clearance (area around the shaft) such as on vehicle drive shafts.

TorqueTrak - Continuous Monitoring

Binsfeld TorqueTrak - Torque and Power Monitoring System

The TorqueTrak Torque and Power Monitoring System (TPM2 series) is a rugged precision instrument designed to measure torque and/or power on rotating shafts in real time using precise strain-gage sensors. The TPM2 is custom designed to fit on shafting as low as .75″ (19mm) and up to 48″ (1220 mm) in diameter. Machine disassembly is not required.

Binsfeld TorqueTrak - Sensor Interfaces System

As the name describes, the TTSI is the interface between the sensor and the customer equipment. On the customer side, the TTSI can provide operator displays, analog I/O, digital communications, and/or discrete digital I/O that are compatible with customer equipment. The TTSI can be provided in a self-contained enclosure, or as DIN rail mountable components that can be added to existing control cabinets. The purpose of the TTSI is to provide a low-cost interface between the sensor and the customer equipment. The main components of the TTSI are a PLC and Operator Display.

TempTrak Rotary Temperature Transmitters - Godet Transmitters

Binsfeld TempTrak - Industrial Interface Rotary Transmitter

The RT501I-IOL is an industrial interface that functions with a variety of Binsfeld Temperature Transmitters. This interface allows Temperature Transmitters to be connected to common industrial field bus. These field buses include, but are not limited to PROFINET, EtherNet/IP, and Modbus TCP/IP. Use with commercially available off-the-shelf IO-Link Masters is required. Digital circuitry from sensor input to signal output.

Binsfeld TempTrak - Multi-Channel Wireless Temperature Measurement System

The RT416-PB is a multi-channel wireless temperature measurement system designed as an upgrade for CAN bus systems to monitor and control temperature on heated godet roll shells on filament spinning machines. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Generous 5 mm clearance between the rotating and stationary parts eliminate rubbing or impacting – a common failure cause in other designs. Error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure. The system features Profibus DP digital communication. It consists of three main components: Controller, Rotating Module with mounting base, and Stationary Module.

Binsfeld - Rotary Temperature Transmitter

The RT220R Rotor is a true drop-in replacement rotating assembly for Rieter and SwissTex rotating transmitters on high-speed godet roll motors (J7-30, J7-31 and J7-32 roll motors). Built to accurately monitor roll temperatures even in the hot, harsh environment of the fiber industry, the RT220R features a rugged mechanical design with fully encapsulated electronics to operate up to 13,000 rpm. In addition, error detection modes protect heater from damage and expedite troubleshooting in the event of a sensor or other failure.

Binsfeld TempTrak - Multi-Channel Temperature Measurement System

Binsfeld TempTrak - One-Channel Temperature Measurement System

The RT381-SP is a one-channel temperature measurement system designed as an upgrade for Teijin-Seiki STA transmitters to monitor and control temperature on heated godet roll shells on filament spinning machines. The system features generous 10 mm clearance between the rotating and stationary parts which eliminates damage due to impact and rubbing. TempTrak® data communications technology is unaffected by dust or debris. Digital circuitry in the rotating transmitter and the stationary receiver are immune to electrical noise and drift. Fault detection modes protect heater from damage and expedite troubleshooting in the event of a sensor failure.