Camec products

Recycling Division - Single-Shaft Shredders

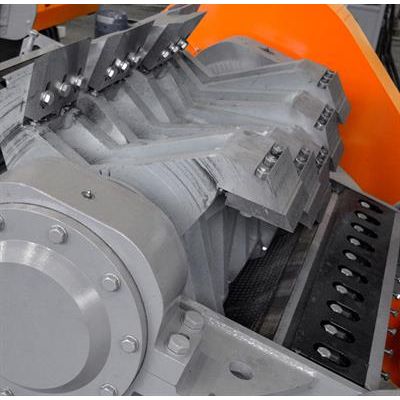

Camec - Model GL620 - Single-Shaft Shredders

GL620 is a high-power single-shaft shredder with a 620-mm rotor, hydraulic drive and a low rpm. The machine can be equipped with a radial pusher or drawer pusher depending on the material to be processed. The larger shredding surface increases production, while the possibility of having a gearmotor with parallel shafts and automatic reverse improves the performance of these single-shaft shredders.

Cameco - Model GR280 - Single-Shaft Shredders

GR280 is the most compact single-shaft shredder in our line.

Recycling Division - Industrial Recycling Systems

Camec - Model SRF-RDF - Industrial Recycling Systems

The system SRF/RDF is designed for the processing of industrial, domestic and commercial waste with the aim to get alternative fuels: SRF (solid recovered fuel) and RDF (refuse derived fuel).

Recycling Division - Two-Shaft Shredders

Camec - Model TR2A140 - Two-Shaft Shredders

The TR2A140 two-shaft shredder is the synthesis of Camec’s historical experience applied to a new idea of recycling: a simple, slim and versatile machine designed to crush organic waste for small facilities like industrial kitchens, ships and small food businesses.

Recycling Division - Four-Shaft Shredders

Camec - Model TR4A400 - Four-Shaft Shredders

Grinder in electro-welded structure (sheets thickness 30 mm). Bearings widely separated from the shredding area. Four 150 mm hexagonal shafts. Independent rotors. Anti-wear steel grid with 50-mm holes.

Recycling Division - Double Rotor

Camec - Model DR450 - Single-Shaft Shredders

DR450 two-shaft shredders were designed to grind materials such as wood, paper, cardboard, branches, etc. The solid structure made of electro-welded 30-mm steel sheets guarantees excellent solidity and a long life. The material is ground by two independent-drive shafts in the cutting chamber, equipped with special tempered steel plates. The operator controls the entire process safely from the control panel.

Recycling Division - Compactors and Presses

Camec - Model P100T/P120T - Vertical Baling Press

Ideal for compacting paper, cardboard, nylon, plastic bodyshells, leather, fabric and similar materials, cans and empty drums. Automatic operation with control buttons on the electrical panel and pressure switch allowing the pressing plate to rise automatically once the pressure has been reached.

Recycling Division - Granulators

Camec - Model MG300 - Granulators

The granulators of the MG line are designed to grind and reduce heterogeneous plastic waste materials from injection moulding, extrusion moulding, blow moulding, thermoforming or for rubber granulation. The rotor’s special configuration and cutting angle between the blade and the counterblade save energy and significantly reduce the formation of dust during the granulation process. The heavy-duty structure with bearings well separated from the cutting chamber means granulation can be done with water jets inside the granulating chamber. This feature makes the machine extremely versatile and appropriate for granulating materials with a low melting point.

Camec - Model MG800 - Granulators

The granulators of the MG line are designed to grind and reduce heterogeneous plastic waste materials from injection moulding, extrusion moulding, blow moulding, thermoforming or for rubber granulation. The rotor’s special configuration and cutting angle between the blade and the counterblade save energy and significantly reduce the formation of dust during the granulation process. The heavy-duty structure with bearings well separated from the cutting chamber means granulation can be done with water jets inside the granulating chamber. This feature makes the machine extremely versatile and appropriate for granulating materials with a low melting point.