- Home

- Companies

- Cathay Composites

- Products

Cathay Composites products

Woven Fabrics

Cathay Composites - Twill Weave

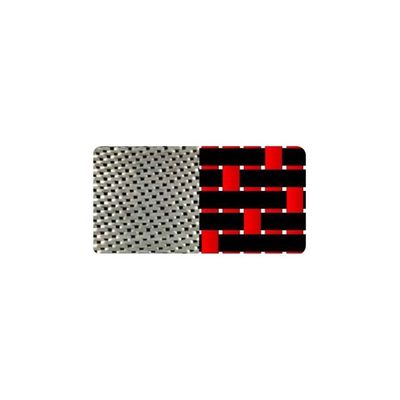

Twill weave consists of a 2×2 or 4×4 pattern. In a 2×2 weave, each tow passes over two tows and then under two tows. This over and under weaving creates a distinct diagonal pattern. The distance between the tow interlaces in a twill weave is longer than with a plain weave. Creating fewer crimps which reduces peak stress points in the weave. Twill weave is pliable and can form to complex contours while still maintaining reasonable stability. It must be handled more carefully than a plain weave fabric to avoid adding distortions to the weave.

Cathay Composites - Satin Weave

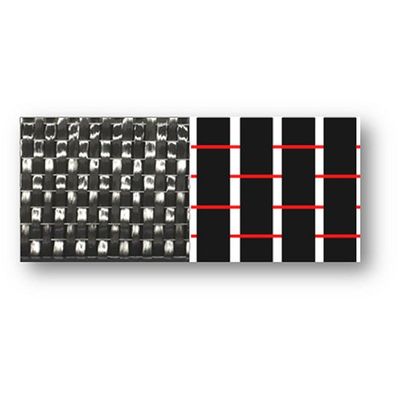

Satin weaves allow formability around complex contours consequently this satin weave offers less stability than other weave forms. The most common satin weaves are four harness satin (4HS), five harness satin (5HS), and eight harness satin (8HS). The number indicates the total number of tows passed over then under. A 4HS weave consists of three tows passed over and then one passed under. For a 5HS, four tows are passed over, and then one under and 8HS is seven tows passed over and one under. The higher the satin weave number, the more formable and less stable it is.

CC Quantum Crack

CC-Quantum - Model CI - Crack Injection Adhesive

CC-Quantum CI crack injection adhesive is a two part epoxy resin adhesive with low viscosity and high penetrating properties. CC-Quantum CI is used for repairing cracks in concrete, masonry and wood.

Others

Cathay Composites - Unidirectional Fabrics

Similar to the Woven Fabric, the unidirectional fabric consists of continuous fibres in the axial or 0° direction. Thin and Light weight, post reinforcement results in minimal change in size and weight to original structure. Unidirectional Fabrics enables excellent formability, capable of wrapping around complex shapes. Alkali and chemical corrosion resistance of various building surfaces (bridges, tunnels).

Cathay Composites - Model NCF Series - Stitching & Non Crimp Fabric

Cathay’s multiaxial (NCF) technologies integrates advanced fibre spreading techniques, high conversion speed, adjustable laying heads and has the capability to manufacture fabrics at variable widths. Multi-axial fabrics comprise of one or more layers of fibres with varying orientation that are stitched together with a lightweight thread.

Cathay Composites - Woven Tapes

Woven Tapes are used as part of load-bearing structural components, they posses good designability features. Carbon fibre bi-directional fabric is suitable for various moulding methods (RTM, VARI). The Woven Fabric can be made from Carbon Fibre, Fibreglass and Aramid (Kevlar) Fibres. Smaller in width compared to Woven Fabrics enables greater variability in manufacturing needs.

Cathay Composites - Braiding/Sleeves Fabrics

Braided: Knitted fabrics such as tapes, sleeves and variable cross-section fabrics. Directly used as reinforcement of composite materials. Excellent structural integrity and structural conformity. It is superior to traditional fibre laminates in terms of production efficiency, automation level, material yield and manufacturing cost.

Cathay Composites - 3-D Woven Fabric

The 3-D Woven fabrics posses high resistance to impact damage due to the improved interlaminar and out of plane strength. The unique design allows for a higher stability capacity. Various cross-section shapes are available. 3D Weaving techniques can be used to produce near-net-shape structures. These preforms can be processed using, for example, resin transfer moulding, to produce composite components extremely efficiently. Cathay Composites offers a full in-house design service from original concept drawings, through to prototyping and into serial production.