Cavitation Technologies, Inc. products

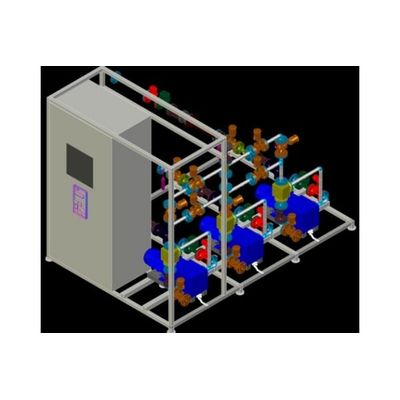

CTI CaviTune - Low Pressure Nano Reactor (LPN)

LPN multistage cavitator designed to achieve improved performance over conventional technologies covering a wide range of applications while processing large volumes of fluids. The improved performance of a low pressure multistage cavitation system is going to be achieved through the introduction of an innovative conceptual designs and usage of advanced computational techniques. LPN systems will depict design methods that combine the best analytical design tools combined with actual computerized test data, resulting in a cost effective flow through cavitation systems with state-of-the-art performance, reliability and high cavitation efficiency.

CTI CaviTune - Laboratory Systems

The laboratory stand is designed for hydrodynamic and cavitation treatment of homogeneous and heterogeneous liquids in order to intensify the processes of mass transfer, emulsification and dispersion, as well as to change the physical characteristics of the treated liquid. Hydrodynamic and cavitation treatment of the liquid is carried out in a flowing hydrodynamic cavitator, model number - LAB101. The principle of operation of the cavitator is based on the non-stationarity of the fluid flows and on the active hydrodynamic effects of the action on the treated substances. The liquid treatment in the hydrodynamic cavitator is implemented by the impulse multifactorial action: vortex formation, microscale pressure pulsations, intensive cavitation, shock waves and non-linear hydroacoustic effects. The design of the hydrodynamic cavitator provides a multiple adjustment of the velocity field and a change in the direction of the fluid flow lines and the components to be mixed.

CTI - Petroleum Upgrading Technology

Based on the results of thorough testing, the Company’s proprietary technology of petroleum upgrading was proven to be capable of breaking down asphaltene agglomerates, improving both the viscosity and API gravity for a prolonged period of time, reducing pumping and atomization costs, facilitating hydrocarbon cracking and increasing the refining yields.