CEC Mining Systems Corp. products

CX-Series Filtration

CEC - Model CX-Series - Ceramic Disc Vacuum (CDV) Filter

HIGHLY ENERGY EFFICIENT DEWATERING OF TAILINGS AND CONCENTRATE PRODUCTS DOWN TO 8% W/W MOISTURE; The CX-Series Ceramic Disc Vacuum (CDV) Filter is a highly energy efficient rotary disc filter that uses ceramic membrane technology instead of cloth. By employing a membrane with pore sizes that are designed to range from 0.75 to 3.0 microns in diameter, the CX-Series filter can recover fine and ultrafine particles in mineral processes to maximize the quality of recovered water. The CX-Series has been installed successfully in tailings filtration applications (“dry-stacking” and underground paste-backfill) and in final concentrate filtration prior to shipment and sale.

Thickening

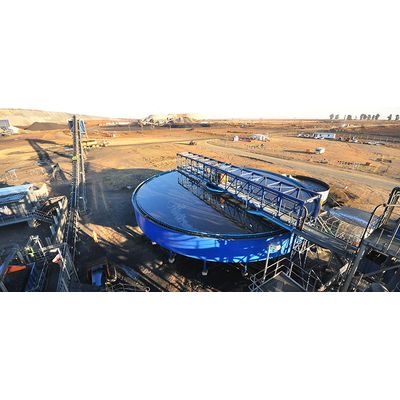

CEC - Thickeners

MAXIMUM UNDERFLOW DENSITY AND OVERFLOW CLARITY WITH BOLTED CONSTRUCTION OPTIONS TO EXPEDITE PROJECT DELIVERY SCHEDULES. Thickeners are used in continuous process applications where solid-liquid separation occurs by sedimentation.

Filtering

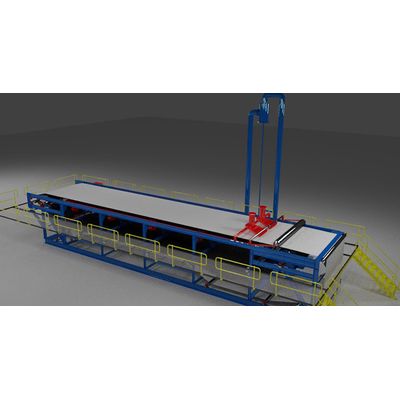

CEC - Model CX-PSS - Horizontal Belt Filter (HBF)

HIGH THROUGHPUT DEWATERING WITH CAPABILITY FOR SOLUBLE METAL PRECIPTATION AND RECOVERY; The CX-PSS Horizontal Belt Filter (HBF) is an efficient and reliable solid/liquid separation unit suitable for dewatering a wide range of materials. Utilizing vacuum filtration, CX-PSS HBF filters have low capital, running and maintenance costs, thereby outperforming traditional rotary drum, disc, tilting pan and table filters in all situations where capacity, efficient cake washing and minimum liquor dilution are required. Furthermore, horizontal belt filters are being well accepted to dewater process plant tailings to be used as mine backfill or sent straight to the dry stack tailings impoundment.

Screening

CEC - Model CX-PSS - Rotaspiral Screen (RS)

FINE SCREENING AND SIZE CLASSIFICATION DOWN TO 75 MICRONS; The CX-PSS Rotaspiral Screen (RS) is an evolution for a conventional drum screen system that removes wood fibre, trash, and oversize particles from slurried, processed ores down to 75 microns. It has been employed successfully in the following applications: