CEC Mining Systems Corp.

- Home

- Companies

- CEC Mining Systems Corp.

- Products

- CEC - Thickeners

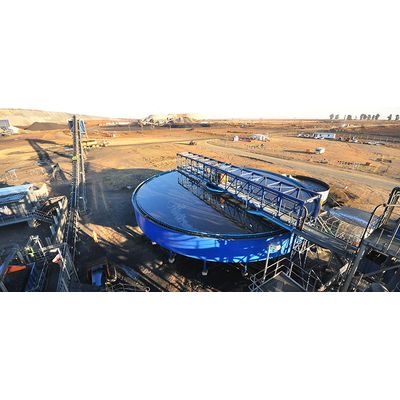

CEC - Thickeners

MAXIMUM UNDERFLOW DENSITY AND OVERFLOW CLARITY WITH BOLTED CONSTRUCTION OPTIONS TO EXPEDITE PROJECT DELIVERY SCHEDULES. Thickeners are used in continuous process applications where solid-liquid separation occurs by sedimentation.

Most popular related searches

solid-liquid separator

solid-liquid separation

thickener

clarifier thickener

liquid separation

water treatment

thickener clarifier

solids separation

water treatment system

decantation

- Concentration, or raising the density, of a mixture of solids and liquids;

- Clarification, or recovering the overflow portion;

- Hydro-separation, where a specific fraction of solids is removed from a mixture;

- Tailings thickening for precious and base metals & minerals

- Treatment of coal slimes

- Gold tailings applications

- Counter current decantation

- Clarifications of pregnant liquor solutions

- Water treatment applications

CECMS can supply a variety of thickener sizes starting from 1 meter diameter pilot-scale units to 90 metres in diameter. We have standard “off-the-shelf” designs, and customized thickener tank, rakes and feedwell designs that are deployed based on the feed conditions and raking capacity. A retrofit service has also been offered to enhance the performance of existing thickeners and clarifiers.

- Delivery time – our modular approach to thickener sizing means that drawing packaged can be assembled quickly and manufacturing can begin almost immediately. We have industry leading turn-around times.

- Low capital cost – our equipment design is conservative yet robust enough to ensure the equipment can still be in operation many years from now.

- International project delivery – our project team is experience deploying installations in challenging jurisdictions. Project expediting and construction schedules are kept in line because of multi-lingual and multi-disciplinary teams.

- Canadian engineering/QA-QC standards – our engineering and design conform to the North American standards, but we’re able to leverage our network of manufacturers overseas to be competitive.

CECMS can supply a “bolted design” for many projects to expedite fabrication, shipping and installation on site.

- No construction works on site

- Simple and easy installation

- Easy to transport

- Easy to re-locate and/or re-purpose

- Low friction rake lift