- Home

- Companies

- Challenger Group

- Products

Challenger Group products

Baling Systems

Challenger Handling - Universal Balers

We have a full range of Universal Balers, built to handle wood shavings, chopped straw, chopped hay and shredded paper. All are designed to meet the exacting standards required in their respective industries. Machines can be produced to make bales of various sizes to suit your requirements. All three models are built with modern programmable logic controllers (PLC) to achieve quick and efficient operations in the automatic mode.

Challenger Handling - Oil Balers

Challenger manufactures a wide range of baling machinery, including those specifically manufactured for baling oil filters. Each baler is designed to suit your needs, boost productivity, and increase the flexibility of use. Oil filters are poured into a hopper and the machine automatically makes heavily compressed bales. In the act of baling, the machine compresses the oil out into a sump. Bales are then delivered into a local container via a bale powered chute and oil is delivered to an IBC or similar container with an immersed sump pump.

Challenger Handling - Pet Bedding Balers

Challenger provide a range of balers specifically tailored to baling pet bedding materials. Balers designed for the Pet trade are available in two basic design formats: volumetric or mass measured, while oil filter balers are available in a number of configurations.

Challenger Handling - Shredded Paper or Cardboard Balers

To support the baling of shredded paper and cardboard, Challenger has developed specific machinery optimised for these materials. Balers are available in a range of dimensions and production outputs, with a selection of optional equipment that can support the complete packaging of materials.

Challenger Handling - Rotary Screens

The Challenger Rotary Screen has been specifically developed for the effective removal of dust and small debris from bulk products, such as woodshavings, woodchips, chopped straw, chopped hay, shredded paper etc. The basic design can be customised, achieving different screening performances and outputs by altering the Screen mesh size, the angle of orientation and the speed of rotation. The mixed material is fed into the top of one end of the machine, and the cleaned material comes out from the lower portion of the opposite end. The dust is then collected in the base and moved to either end or the centre by a screw conveyor. A small dust extraction point can be added to the side of the unit to keep a small negative pressure, keeping external leakage to a bare minimum. This machine is very cheap to run by comparison to other forms of dust removal and has very few moving parts, making it the ideal choice for low bulk density raw material dust removal.

Crushers & Compactors

Challenger - Large Engine Crusher

The Challenger Large Engine Crusher has been specifically developed to reduce large engines and gearboxes into small particles. This enables the aluminium to be separated from the ferrous and other metallic components to ease sorting. The Large Engine Crusher has both a fully automatic cycling mode and a manual mode, and can be supplied with a number of optional extras including diesel/petrol engine drive, hoppers, support frames, hydraulic oil cooler, adjustable finished particle device, warning alarms, feed and discharge conveyors etc.

Challenger - Can Crushers

The Challenger Can Crusher range is designed to crush all sorts of metal cans, up to 25-litre (5 gallon) capacity, to a fraction of their original height. The standard machine is available with either manual or semi-automatic controls and can be desk or wall mounted to save space if required. In addition, it can be provided with a wide variety of options, including ATEX certification, if necessary. Fully automatic versions are available on request.

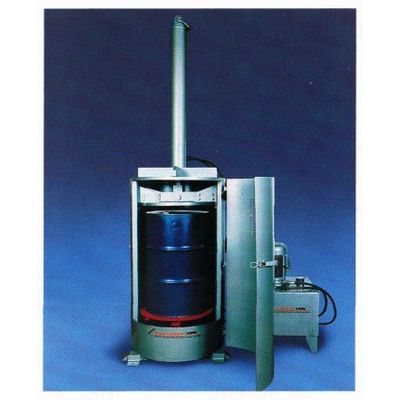

Challenger Drumtech - Drum Crusher

The Challenger Drumtech Drum Crusher has been designed to crush unusable 205 litre capacity steel drums to a fraction of their original heigh,t to keep both site storage and transportation costs to a minimum. The steel drum is manually placed into the cabinet, the operator closes the door and presses the “Start Cycle button” and the operation continues thereafter automatically. The heavy-duty structure is designed to take the stresses imposed by the hydraulic cylinder, and the door is fitted with a positive mode interlock to ensure operator safety.

Waste Processing & Recycling Systems

Challenger - Steam Screw Processing Systems

As the name suggests, Steam Screw systems use steam both within the screw conveyor mechanism, and pumped into the pre-shredded medical/clinical waste to thoroughly and reliably sterilise the ‘floc’. For a full suite of processing, the unit also features a shredder, a lifting tipper, a conveyor and waste compactor, as well as the steam screw itself. Options include: Duty standby shredder; Overhead crane dryer; Feed to moving floor trailer(s).

Challenger - Thermal Oil Screw Processing System

Thermal Oil Screw Systems use high temperature oil within the screw conveyor mechanism to turn moisture in the shredded medical or clinical waste into steam to thoroughly and reliably sterilise ‘the floc’. As well as the Thermal Oil Screw system itself, the unit also features a lift tipper, conveyor, shredder and waste compactor, for comprehensive disposal of clinical waste. Options include: Duty standby shredder; Overhead crane; Dryer; Feed to moving floor trailers.