- Dust collectors

- Liquid-Solid Separation - Water Filter Fabric Roll and Ready-Made Filter Fabrics

- Liquid-Solid Separation - Micron Rated Liquid Filter Cloth and Filter Bags

- Liquid-Solid Separation - Bolting Cloth/Pring Mesh/Flour Mesh/Filter Mesh

- Liquid-Solid Separation - Filter Press and Filter Plates

- Liquid-Solid Separation - S.S. Filter Housing

- Liquid-Solid Separation - Liquid Filter Cartridges

- Liquid-Solid Separation - Filter Belt for Belt Filter and HVPF

- Air-Solid Separation - Low-Medium Temperature Dust Filter Material

- Air-Solid Separation - Medium-High Temperature Dust Filter Cloth

- Air-Solid Separation - High Temperature Resistance Dust Filter Material

- Air-Solid Separation - Filter Bag Housing and Accessories

- Air-Solid Separation - Cartridge Dust Collector and Accessories

- Air-Solid Separation - Clean Room Filters and Filter Materials

- Air Slide Solutions

Changzhou Zonel Environmental Technology Co., Ltd. products

ZONEL FILTECH - Model ZF/DC/V - Vertical Cartridge Dust Collectors

General introduction of the vertical installing cartridge dust collector: The vertical installing cartridge dust collector as usual designed for some industrial which the dust air with high dust content, at meanwhile with a high filter speed / Air cloth ratio, the special designed air way makes the filters with a perfect operation state. The vertical installed filter cartridges will help to solve the purging problems, also can avoid the dust drop from above filters so as to guarantee the filter houses always with a lower resistance and increase the service life. Applications: Metal processing, mining, cement industries, ceramic industries, carbon black industries, pharmaceutical industries, chemical plants, metallurgy industries, hot air spray industries, rubber industries, battery industries, mixing plants, and other powder processing occasions, etc.ZONEL FILTECH - Model ZF/PT - Portable Filter Cartridge Dust Collector

The portable dust collector mainly equipped for the circumstance which dust cause positions not fix or temporary dust points for dust collection and fume removal. The properties: 1.Easy to move, can collect the dust in different positions easily. 2.Suitable for some fine fume collection, such as welding fume; also suitable for some big particles collection. 3.Installed the high efficiency filter cartridge, filter efficiency more than 99%, the service life of the cartridge more than 1 year, easy maintenance. 4.With self-clean system, easy to purging the filter cartridges. 5.With the shelf and flexible dust suction pipe, the length can customize according to client’s requirements. Application: Mainly play the role as Welding working shop dust collector, polishing plants dust collector, food industries dust collector, pharmaceutical plants dust collector, the packing position of the powders dust collector and other occasion need to purify the dust air.Zonel Filtech - Filter Press Belt/ Vacuum Filter Belt/ Forming Belt

Zonel Filtech provide replacement filter belt for various filter machines, such as horizontal vacuum belt filters (offer vacuum filter belts), belt filter press (offer press filter belt), HVPF belt filters (tower belt filter), drum filters, paper or nonwoven forming machine, etc.

Zonel Filtech - Absolute Rated Filter Bag / Absolute Efficiency Filter Bag

For the traditional designed nonwoven liquid filter bags, as usual the filter efficiency is around 60~70%, which just can be used for some primary filtration, for some high efficiency request occasions is not applicable.

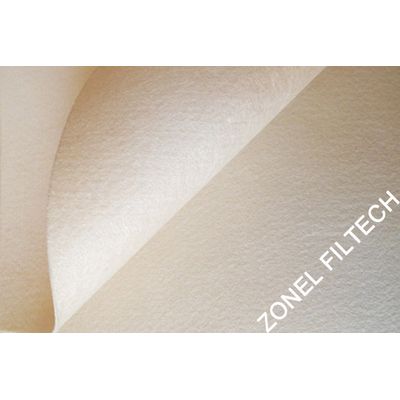

Zonel Filtech - Polyester Needle Felt Filter Cloth for Dust Filter Bags Production

The Polyester (PET, terylene felt) needle felt nonwoven filter cloth with the properties of high tensile strength, super abrasion resistance, good acid resistance, food grade, one of the most economical filter materials that is widely used in various industrials applications for dust collection usage (dust filter cloth for dust filter bags production).

Zonel Filtech - Anti-Static Needle Felt Filter Cloth/ Anti-Static Dust Filter Bags

The anti-static filter cloths from Zonel Filtech was designed for dust collection (anti static dust filter bags) in the occasion of dust air with some flammable or explosive materials, such as the flour dust, aluminum dust, coal dust, and some explosive powder materials in the industries such as chemical, etc.

Zonel Filtech - Acrylic Needle Felt Filter Cloth/PAN Needle Felt

Homo-polymer acrylic needle felt / Acrylic needle felt / polyacrylonitrile needle felt (PAN needle felt filter cloth) well known for its hydrolysis resistance performance, ZONEL FILTECH research and developed the special PAN filter cloth for dust collection.

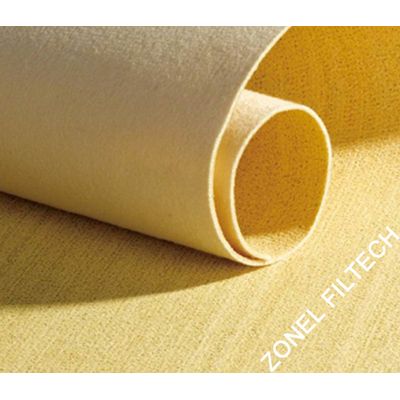

Zonel Filtech - Aramid Needle Felt Filter Cloth/ Nomex Filter Cloth

The Aramid fiber/Meta-aramid fiber for needle felt filter cloth production also called Aramid fiber 1313 in China, and Nomex® is one kind of the aramid fibers produced by Dupont®.

Zonel Filtech - PPS/Ryton Needle Felt Filter Cloth, PPS Dust Filter Bags

PPS PPS (polyphenylene sulfide, Ryton® , Procon®) is one of the best filter materials with the properties high temperature resistance, anti -acid, anti-alkali, hydrolysis resistant. The PPS filter bags mainly used for purifying the dust air which include some acid or alkali materials under the high temperature, such as the thermal power plants boils exhausting gas cleaning, waste incinerators fume removal, etc.