Cone Drive Operations, Inc products

Worm Gearing - Worm Gearing - Servo

Cone Drive - Gearbox for High Speed Precision Motion Control Applications

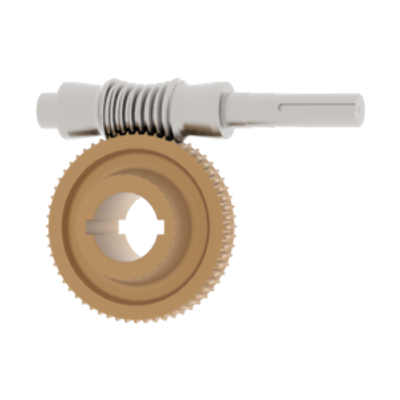

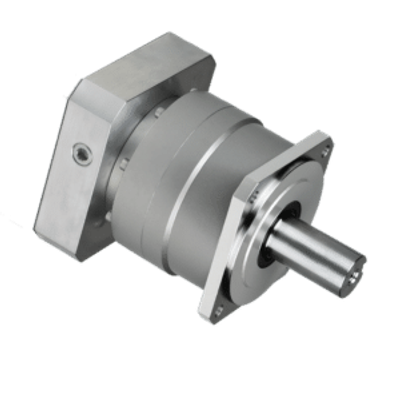

The Series W gearbox by Cone Drive is engineered to meet the rigorous demands of high-speed precision motion control applications. At the core of this compact gearbox is Cone Drive’s proprietary double enveloping worm gearing, which is reinforced by two high-speed angular contact bearings. This robust design allows for exceptional torque capacity and durability. The gearbox is available in configurations with standard, low, or zero backlash, accommodating a wide range of technical requirements. Key features include double enveloping worm gearing for increased contact and load capacity, two input bearings, zero backlash bellows coupling, and an aluminum housing. The Series W gearbox is also engineered for optimal performance with approved lubricants and operates within a specified temperature range to prevent overheating. It comes with a best-in-class lead time and is backed by a five-year warranty. The product is well-suited for applications where high precision and reliability are critical, offering customizable solutions to meet various application needs.Cone Drive - Stainless Steel Servo Gearbox

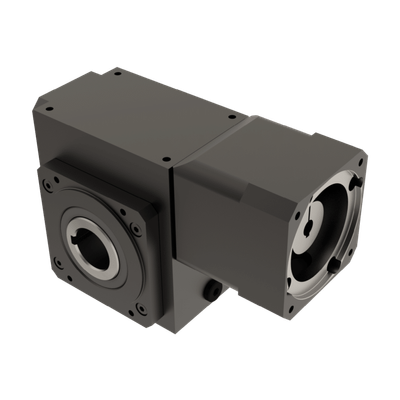

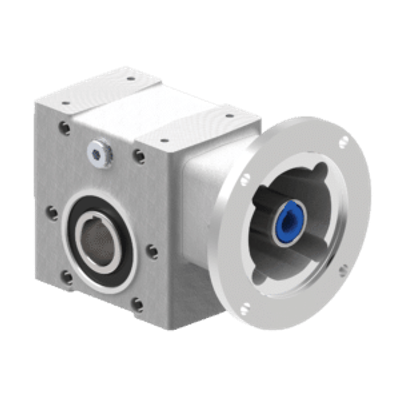

The Series FS Stainless Steel Servo Gearbox from Cone Drive offers a robust solution for applications demanding hygienic precision. Its smooth, stainless steel housing is designed to prevent bacterial formation, ensuring compliance with strict hygiene standards. Key technical features include double enveloping worm gearing, which provides higher torque capacity and durability, and low or standard backlash options. The gearbox utilizes 316 stainless steel components and has an IP69k rating, making it suitable for wash-down environments. It supports various mounting options and offers a five-year warranty. The design accommodates both forward and reverse operation of the worm input shaft and includes a cooling coil feature for heat management during continuous, high-power operations. This gearbox also maintains high performance across a range of operating temperatures and lubrication conditions. Cone Drive's Product Development Laboratory provides rigorous testing and validation to ensure optimal performance and reliability of the FS Series Gearbox.