ConVault, Inc. - Oldcastle Precast products

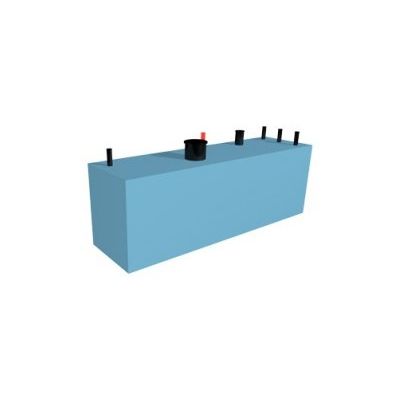

ConVault - Split Tanks

ConVault tanks can be partitioned, in either direction, into multiple separate storage tanks for solutions that require the storage or dispensing of different types of liquids such as gasoline and diesel, from a single Convault. This solution allows for multiple liquids to be stored in a small footprint.

ConVault - Oil & Chemical Storage Tanks

ConVault oil & chemical storage tanks provide safe and efficient storage of environmentally hazardous chemicals and petroleum products including: Waste Oil, Used Oil, Vegetable/Animal Oils, Methanol/Urea, Antifreeze, Hazardous Waste Oil.

ConVault - Primary Steel Tank

The steel tank is isolated from the concrete encasement to assure corrosion protection. ConVault® steel tanks are made of 1/8`, 3/16` or 1/4` thick steel, depending on warranty and tank size. The steel tank contains and holds the liquid fuel, which is the primary function of the tank. To make the steel tank systems fit for their function; the tanks are made in accordance with the UL standard 142 and ULC standard S601.

ConVault - Secondary Containment

A high performance, 30 MIL high density polyethylene membrane encloses the primary tank and provides secondary spill containment. The second stage of manufacturing consists of wrapping the steel tank with a minimum of 1/4” thick Styrofoam (foam) insulation and an impervious barrier of 30-Mil high-density polyethylene membrane (HDPE). The 30-Mil HDPE provides containment for the remote possibility of a fuel leak through the steel tank. A leak detector pipe terminating in the secondary containment provides a positive-proof that the tank is not leaking. Another advantage of the 30-Mil HDPE is that it shields and protects the steel tank exterior from coming in direct contact with concrete and thus minimizes the potential risk of tank external corrosion. Certain Authorities Having Jurisdiction require metallic secondary containment.