Crown Machine UWP, Inc. products

Pelletizers

Crown - Underwater Pelletizer

Output ranges from (2.2 lb/hr or 1 kg/hr) to (60,000 lb/hr or 30,000 kg/hr) for pellet sizes from Large (.060 - .250" or 1.2 - 10mm) to Small Micro (.010 - .050" or .25 - 1.1mm) depending on die, pelletizer model and resin. Suitable for high output pelletizing, compounding, manufacture of color concentrate, scrap recovery, pilot operation, and research and development, and is able to process a wide range of polymers such as hot melt adhesives, thermoplastic rubber, polyester, nylon and other thermoplastics; especially for TPE, TPU, PA, PET, TPV, ABS, PP, PVC, Wax, Adhesives, Glass filled material, Carbon fiber filled compounds and 95% Metal filled compounds

Crown - Dry Face Pelletizer

Output ranges from (2.2 lb/hr or 1 kg/hr) to (60,000 lb/hr or 30,000 kg/hr) for pellet sizes from large (.060 - .250" or 1.2 - 10mm) to Small Micro (.010 - .050" or .25 - 1.1mm) depending on die, pelletizer model and resin. Suitable for high output processing, compounding, manufacture of color concentrate, scrap recovery, pilot operation, and research and development, and able to process a wide range of polymers such as hot melt adhesives, thermoplastic rubber, polyester, nylon and other thermoplastics; especially for TPE, TPU, PA, PET, TPV, ABS, PP, PVC, Wax, Adhesives, Glass filled material, Carbon fiber filled compounds and 95% Metal filled compounds.

Crown - Water Ring Pelletizer

Output ranges from 20 lbs/hr to 15,000 lbs/hr. Utilizes hot die face method to cut pellets, then pellets are thrown into a water circulating cooling ring. Produces consistent sized dry pellets. Balanced melt flow from upstream equipment to die-cutting surface with no flow interruption. Able to process PE, PP, LDPE, LLDPE, HDPE, HMWPE - HPDE, ABS, EPS, PS, and many other types of materials. Easily accomodates a variety of extruder centerline heights.

Extruders

Crown - Twin Screw Extruders

Ideal for production of polymers to enhance physical, electrical, mechanical, optical and chemical properties. Used for various processes such as compounding, pelletizing, pipe production and coating, profile and sheet extrusion, wire coating and blown film. Available in 30mm, 40mm, 50mm, 60mm, 70mm, 80-83mm, 90-92mm, 120-133mm, 160-177mm and 240-260mm diameters with variety of standard and custom-designed screws and barrels are available for various applications. Can be assembled in any combination to provide plasticizing of raw material feeding, ventilation or gas extraction

Crown - Single Screw Extruder

Ideal for production, material testing, new product development and quality control purposes, and used in various processes such as compounding, pelletizing, sheet extrusion, pipe extrusion, wire coating and blown film. Available in 1 1/2", 2 1/2", 3 1/2", 4 1/2", 6", 8", 10" and 12" diameters with variety of standard and custom-designed screws and barrels are available for various applications.

Screen Changers

Crown - Dual Bolt Hydraulic Screen Changer (Polymer Filtration)

The dual bolt hydraulic screen changer allows for the changing of polymer filtration screens without stopping production by alternating bewtween to bolt positions. All gas in the polymer melt can be discharged through an advanced gas exhaust system design. This provides continuity and stability of the production process. Dual bolt hydraulic screen changers are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Crown - Single Bolt Hydraulic Screen Changer (Polymer Filtration)

Single bolt hydraulic screen changers use two working filter screen and are used in compounding, masterbatch, recycling, sheet extrusion, profile extrusion, pipe production, pipe coating, and biaxial orientation.

Granulator

Crown - Heavy Duty Granulator

Controlled reclamation of solid materials, pipes, thick bulky parts, heavy wall fittings, thick purgings, blocks, rods, high impact applications, haystack film, bailed fiber, thick sheet, cast blocks, engineered plastics and tires.

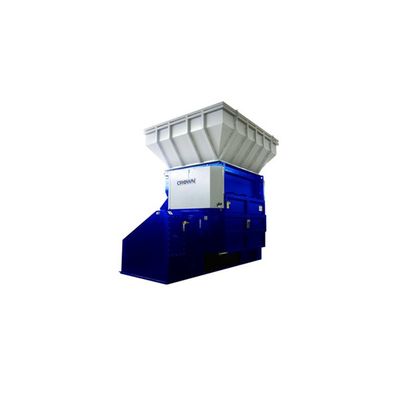

Shredders

Crown - Single Shaft Shredders

Cutting Chambers: made of high hardness steel that is CNC machined and fine ground before assembly. Heavy wall thickness and high grade materials increases the durability of the machine.

Crown - Film Shredders

Screenless Operation: material is cut into uniform pieces, the shredder operates without a screen, although a screen can be installed as an option when smaller particle sizes are required.