CTP Chemisch Thermische Prozesstechnik GmbH / CTP Air Pollution Control GmbH products

Solutions - Systems - Thermal Systems

CTP - Regenerative Thermal Oxidation System (RTO)

The VOXcube purifies organic (VOC) and specific inorganic pollutants in the waste gas. The system is suitable for flow rates up to 125.000 Nm³/h, with a wide variety of concentrations and contaminants. For waste gas temperatures from -20°C up to +350°C.

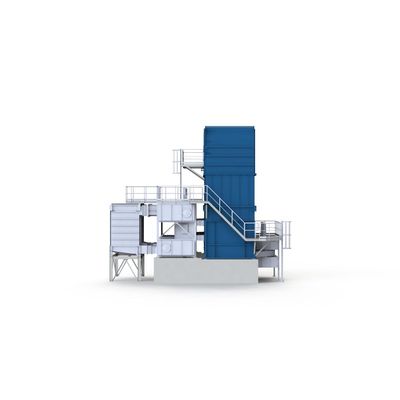

CTP - Regenerative Thermal Oxidation System (RTO)

The perfect CTP solution as an air pollution control treatment for increased solid matter content (dust), sticky substances or corrosive components in the waste gas. The AutoTherm is suitable for flow rates of up to 300,000 Nm³/h, independent of the concentration and the nature of the contaminants. For waste gas temperatures from -20°C up to +400°C.

CTP - Direct Thermal Oxidation (TO) System

For safe removal of highly contaminated, i.e. halogenous, waste gas streams and liquid waste as well as wastewaters, especially in the pharmaceutical, chemical and petrochemical industry. CTP‘s MultiTherm is a combined process. It consists essentially of a thermal oxidation and one or more upstream or downstream processes fitted to the application. These could be heat recovery, wet scrubbing and DeNOx, among others. Our burner system has managed the simultaneous combustion of many highly variable waste streams.

Solutions - Systems - Catalytic Systems

CTP - Recuperative Catalytic Oxidizer (CO)

For high cleaning efficiency, the RecuKAT`s attractive economic performance is due to the low reaction temperature of the CTP catalysts. CTP can refer to more than 30 years of experience with catalysts in industrial applications. The RecuKAT is suitable for small to medium gas flows with low or high concentrations.

CTP - Regenerative Catalytic Oxidation (RCO) System

The AutoKAT combines the advantages of regenerative thermal oxidation with those of catalytic oxidation. The AutoKAT is a very cost-effective alternative for well understood waste streams. Existing RTO systems can be upgraded to an AutoKAT.

CTP - Selective Catalytic Reduction System (SCR)

CTP’s SCR systems are used in industrial processes with a wide variety of gas volumes and NOx concentrations. These systems are also suitable for increased particulate content.

CTP - Regenerative Selective Catalytic Reduction System

The perfect CTP solution for the reduction of NOx. A special feature about the CTP AutoNOx is the fact that it can be adapted to meet a wide variety of special customer requirements.

Solutions - Systems - Thermal Oxidation Systems - Hybrid Systems

CTP - Regenerative Thermal Oxidation System (RTO)

The perfect CTP-solution for a combined cleaning of organic pollutants (RTO) and nitrogen oxides (SCR) at high efficiencies. The RTO-i-SCR is suitable for flow rates up to 300.000 Nm³/h at raw gas temperatures up to +200°C.

VOCNOxTherm - Selective Non-Catalytic Reduction System

The VOCNOxTherm system combines low operating costs and excellent cleaning efficiency of an RTO with the NOx reduction of an SNCR. In several applications the VOCNOxTherm eliminates the need for an additional and complete SCR system.

CTP - Hybrid Regenerative Thermal Oxidation System (RTO)

The perfect CTP-solution for combined cleaning of low laden organic waste gas flows and high caloric off gas and/or liquids even without LEL protection. The Hybrid-RTO is especially suitable for small flows at concentrations > LEL, which occur continuously or discontinuously. Design of the raw gas injection is possible in ATEX.