Cyclonaire Corporation products

Semi-Dense Phase Conveying System for Soil Remediation

Cyclonaire - Vacuum Loaded Semi-Dense Phase Conveyor

The C Series is a vacuum loaded semi-dense phase conveyor with a capacity of 5-50+ TPH. It is best suited for powdered, granular or pellet abrasive materials that are friable. Medium pressure blower air is used to venturi-vacuum load and convey material at intermediate line velocities and material-to-air ratios for less abrasive wear and particle degradation. The unit is capable of multiple applications, from bulk carrier, IBC and bulk bag unloading to in-plant transfer. With optional load cells, the C Series can also weigh and batch multiple materials with inventory control. The total 15 PSIG output of the blower is used in the convey mode for maximum efficiency. During vacuum loading the blower air is automatically routed through a proprietary venturi to induce a deep vacuum.

Mechanical Conveyors

FlexFlite - Flexible Screw Conveyor

The FlexFlite Flexible Screw Conveyor is a versatile new tool for conveying a wide range of dry solids over distances up to 100 feet. They are mechanically simple, easy to operate, easy to clean, and readily portable, making them ideal for use with bags, bins, hoppers, or weigh stations.

Dilute Phase

Filter Receiver

Cyclonaire’s Filter Receiver ensure excellent filtration of unwanted materials and particles. The Filter Receiver provides automatic air filtration and dust control, easily trapping unwanted airborne material. Preset timers clean the filter media automatically with pulse jet reverse air flow and enable captured material to be collected for use. Our Filter Receivers can be fully integrated with filter bag and filter cartridges. A wide array of sizes with custom sizing and features are also available.

Dust Collection

Dust-Free Bag Dump Station with Self-Cleaning Filter for Material Handling Systems

Cyclonaire’s Bag Dump Station offers safe and simple handling of bagged materials in a dust free environment. The operator-friendly design includes bi-fold hinged door, heavy-duty bag support grate, and easy bag piercing. Self-contained fan and self-cleaning pulse jet style filter elements trap fugitive dust for recycling. The unit has a large work platform, easy controls, and a working hopper that integrates easily into your material handling system.

Bulk Bag Unloader

Cyclonaire’s quality built bulk bag unloading station is the most flexible and most customizable choice for your demanding needs and cost conscious budget. Start with our basic heavy duty, carbon steel box tubing frame, custom built to handle any weight or size of bulk bags. Add custom features for your needs— electric hoist, bag tensioners, bag massaging paddles, load cells or glove box—plus more. Get the economy of bulk bag supply with the safety, convenience, and affordability of Cyclonaire bulk bag unloaders.

Bin Vent / Dust Collector

Cyclonaire brand bin vents and dust collectors provide excellent filtration at destination points such as bins, hoppers, and silos. Installation is quick and easy with flanged outlet for dust discharge. Automatic timers clean the filter media with pulse jet reverse flow air; dropping retained material back into the process. Wide array of sizes available; custom sizes and features are also available.

High-Efficiency Dense Phase Conveying System for Industrial Applications

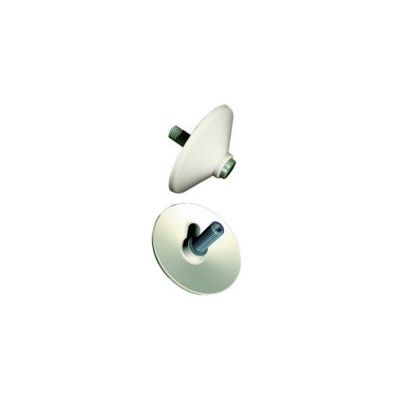

High Pressure Line Injectors for Conveying Systems

Cyclonaire’s convey line injectors operate at pressures up to 100 PSIG. Metered volumes are regulated by a patented needle-type flow adjustment valve complete with adjusting nut and rubber sealing boot. Installation is quick and simple, with little to no maintenance. Available in Nylon, Aluminum and Stainless Steel.

Cyclonaire - Dust Reclaim System

The automated C&C Dust Reclaim system preserves air quality and conserves valuable material by capturing dust from silo filling operations and automatically returning it directly to the source silo or another destination. Cyclonaire’s convenient, ground-level Pulse Jet Dust Collector is paired with a gravity-fed CycloLok dense phase pneumatic conveyor for a total collect and convey system. The unit is equipped with on-board controls for automatic, unsupervised operation and no need to empty dust from the hopper. The system operates on plant air and runs only when needed. There is no separate blower and no wasted energy – further ensuring efficiency.

CycloLok - Abrasive Material Handling with CycloLok Dense Phase Conveyors

For low-volume pneumatic conveying of abrasive materials, such as cement, slag, and fly ash, move product efficiently with CycloLok dense phase conveyors. Economical CycloLok conveyors are designed to handle highly abrasive and friable materials and to withstand harsh environments or high temperatures. Their robust, wear-resistant characteristics make them ideally suited as alternatives or replacements for conventional rotary airlocks, which may be prone to rotor and housing wear when used with highly abrasive materials. CycloLok conveyors also are used to reclaim material from dust collectors or precipitators.

Components

VibraPad - Variable Aeration and Vibration Kits for Bridging Prevention in Bulk Material Handling

VibraPad Aeration Systems, available in assorted standard sized kits, from 2- pad kits up to 24- pad kits with installation hardware, increase the flow of dry bulk materials for reliable and efficient product transfer from hoppers, bins, and silos. This product combines variable aeration and vibration to counter bridging, rat-holing, and compacting that can occur during processing and storage. Kits include parts needed for a complete system: controls, piping, plumbing, fittings, hoses, wiring, and valves. Cyclonaire can also custom fit a VibraPad Aeration System to fit your exact application.