- Home

- Companies

- Datum Electronics

- Products

Datum Electronics products

Datum Electronics - Model Auger Hawk - Helical Screw Pile Torque Sensor

The Datum Electronics Auger Hawk is a family of wireless torque monitoring systems designed for operators installing helical piers, screw piles, and ground screws. Built for challenging environments, Auger Hawk delivers real-time torque, thrust, and depth data directly to your mobile device, helping you efficiently verify load-bearing capacity, meet engineering specs, and guarantee compliance. With proven accuracy and straightforward installation, it’s the modern solution for confident, code-compliant foundation work.Datum Electronics - Model M425 - Rotary Torque Transducer | Inline Torque Monitoring

The M425 is a precision dynamic torque sensor designed for inline torque, speed, and power measurement in rotating systems. Built with a non-contact signal transmission system and available in a range of torque capacities, it’s ideal for monitoring torque in motor, gearbox, pump, and drivetrain testing.

With accuracy up to ±0.1% and digital or analogue outputs, the M425 delivers reliable, repeatable data for R&D, test rigs, and industrial applications. Its robust, compact design and flexible output options makes this torque transducer easy to integrate into demanding environments.

Datum Electronics - Model RS425 - Non Contact Torque Transducer | High Range Torque Monitoring

The RS425 is a high-performance, contactless torque sensor designed for inline installation in high torque drivetrains and test rigs. With a bearingless architecture and strain-gauged shaft, it delivers accurate, friction-free torque monitoring in both static and dynamic applications. Its robust design supports high-speed torque in harsh environments while maintaining long-term reliability and minimal maintenance.

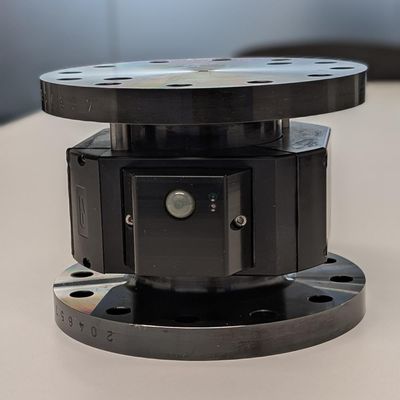

Datum Electronics - Model FF425 - Non Contact Flanged Torque Transducer | Shaft Torque Monitoring

The FF425 is a fully contactless flange-to-flange torque sensor designed for inline installation in drivetrains and test rigs. With standard DIN flange couplings at either end, it offers seamless integration into existing setups, delivering precise shaft torque, speed, and power data across a wide range of applications. Whether you require rotary torque monitoring in high-speed systems or are validating power output in industrial machinery, the FF425 offers a reliable, drop-in solution.Datum Electronics - Custom Torque Sensors for OEM & Industry

Datum Electronics specialises in designing and manufacturing custom torque sensors for applications where standard products aren’t suitable. Whether you’re working with non-standard shaft geometries, extreme torque ranges, or unique mechanical layouts, our engineering team can deliver tailored solutions that meet your exact requirements. From one-off prototypes to fully integrated OEM systems, we provide rotary and static torque sensors built to fit your environment — not the other way around.Datum Electronics - Tractor PTO Torque & Power Monitoring System

The Datum Electronics PTO (Power Take-Off) Torque and Power Monitoring System collects and logs the torque, shaft speed, and transmitted power accurately when testing systems driven from all standard PTO shafts. Designed for rugged field environments, the system delivers reliable, high-accuracy data (±0.1%) even under demanding tractor-powered applications—helping users validate equipment performance, optimise transmission efficiency, and ensure safe, effective operation in agriculture and industry.Datum Electronics - Model 460 Series - Bolt-On Strain Sensors

Datum Electronics’ strain gauge sensors provide a reliable and cost-effective way to measure strain on metal structures without welding or bonding. Designed for harsh conditions, these sensors convert mechanical strain into accurate electrical signals, enabling real-time monitoring of stress, load, and fatigue across a range of sectors.Datum Electronics - Model Custom - Bolt-On Strain Sensors

Our custom bolt-on strain gauge sensors are designed and manufactured to your application, based on your drawings and specifications, including all types of output formats. Ideal for dynamic load monitoring, capable of measuring and monitoring axle stress and weight with high accuracy. Do you have an application for strain gauge measurement that requires a quick and simple installation, repeatedly, in multiple locations? Perhaps you need a sensor with high environmental protection, which removes the necessity for time-consuming cleaning, complicated soldering and messy strain gauge adhesives?

Datum Electronics - Marine Shaft Power Meter System

Datum’s Marine Shaft Power Meter Systems are developed to provide real time and ongoing power monitoring data on propulsion shafts, thrusters and diesel generators. These devices are commonly used for fuel economy monitoring and equipment maintenance planning programs and can be used in conjunction with our EEXI | ShaPoLi solution to keep vessel owners in line with the latest legislation. The Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) requirements were made legally binding by the MARPOL Annex VI, the first climate change treaty to be adopted since the Kyoto Protocol.