Desmet products

Solvent Extraction

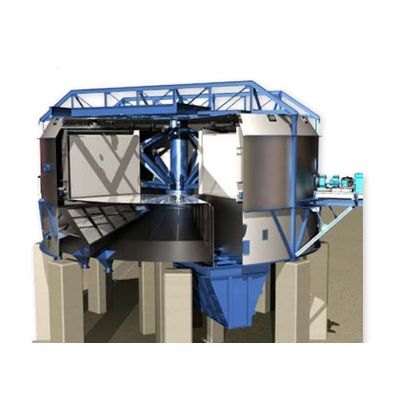

Extractor

Advantages Low Upstream Energy Demand [when Soya only]. 15% less upstream flaking energy than shallow material layer extractors require High Extraction Efficiency. 50% of oil is washed out during the slurry filling process. 100% miscella/material contact by full immersion in miscella between dividing walls. Complete separation of miscella concentrations by dividing walls. Online adjustment of miscella staging for varying material percolation rates. Self-cleaning miscella spray nozzles insure even miscella distribution Low Downstream Energy Demand. 10-15 minute drip time provides 26-30% solvent retention. 30% open area extractor screen provides 26-30% solvent retention. 304 SS self cleaning extractor screen provides 26-30% solvent retention. 2 mm wide slots in extractor screen provides 26-30% solvent retention.

Extractor

High Extraction Efficiency: Long extraction time insures thorough miscella/material contact. Excellent miscella/material contact via full immersion in early extraction stages. Upward sloped material layer insures countercurrent miscella flow. Separation of miscella concentrations by rakes between miscella stages. Online adjustment of miscella staging for varying material percolation rates Low Downstream Energy Demand: 15 minute drip time provides 26-28% solvent retention. 30% open area extractor screen provides 26-28% solvent retention. 304 SS self-cleaning extractor screen provides 26-28% solvent retention. Uniform material discharge via scraper insures uniform DT steam consumption

Fat Modification

Fully Automated Fractionation Technology

When oil is gently cooled, crystals will form spontaneously in the melt. After sufficient maturation time, these crystals can be filtered from the remaining liquid fraction, and this process thus results in 2 products: a solid fraction enriched in high melting crystals, and a clear liquid fraction depleted from high melting crystals. Typically this process is applied on oils that have an appreciable content of high melting components. The prime example is palm oil: this semisolid fat is not only the most produced oil in the world, it is also the most fractionated oil in the world since it serves as natural source for interesting solid fats as well as excellent liquid fractions. FlexiFrac technology successfully combines the two aspects of the process, a controlled, selective crystallization and high-pressure filtration of the crystal suspension, into a smooth and flexible plant operation for a wide spectrum of fats and oils.

Free Fatty Acids Fractionation

A specific non-food application of FlexiFrac technology can be found in the fractionation of fatty acids. The splitting and concentration of different types of fatty acids is crucial in order to produce basestock for industrial lubricants, cosmetics, softeners… Although there is a wide selection of different technologies available today, each with its own advantages and limitations, dry fractionation technology is gaining attention and credibility because of its lower environmental impact, while high levels of purity can still be obtained.