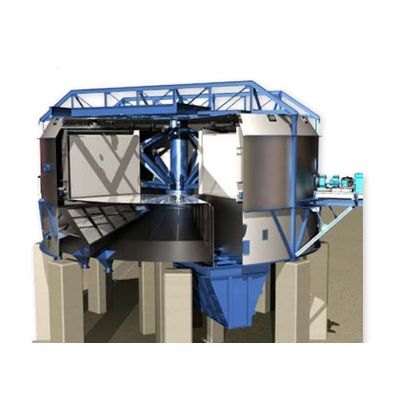

Model Reflex -Extractor

Advantages Low Upstream Energy Demand [when Soya only]. 15% less upstream flaking energy than shallow material layer extractors require High Extraction Efficiency. 50% of oil is washed out during the slurry filling process. 100% miscella/material contact by full immersion in miscella between dividing walls. Complete separation of miscella concentrations by dividing walls. Online adjustment of miscella staging for varying material percolation rates. Self-cleaning miscella spray nozzles insure even miscella distribution Low Downstream Energy Demand. 10-15 minute drip time provides 26-30% solvent retention. 30% open area extractor screen provides 26-30% solvent retention. 304 SS self cleaning extractor screen provides 26-30% solvent retention. 2 mm wide slots in extractor screen provides 26-30% solvent retention.

Low Maintenance

- 80% less drive energy than shallow bed extractors provides lowest wear

- Bevel gear drive – no chains – leads to minimum maintenance

- 304 SS extractor, low friction screen lasts the full life of the extractor

Low Solvent Loss

- Plug seal screw conveyor feed insures minimum air intake to the process

- Only one shell penetration for driving extractor minimizes fugitive solvent loss

Other Advantages

- Internal miscella filter insures industry’s cleanest miscella, < 0.1% solids

- Edible oil lubricated bottom bearing prevents mineral contamination of oil

- Miscella hoppers run empty and stay clean of material fines