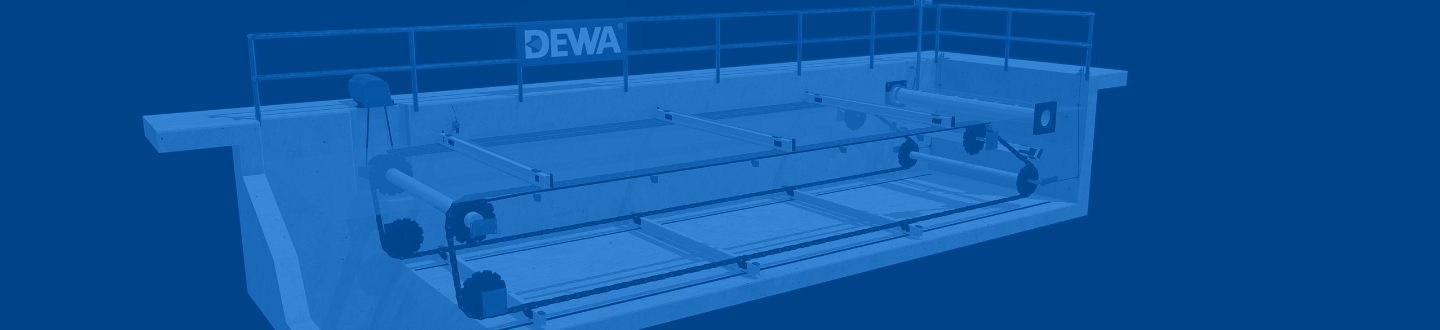

Dewaco Ltd.

We provide complete sludge thickening, dewatering, and sludge removal systems with extensive experience. Dewaco does not only design and manufacture the equipment. We also install, upgrade, and maintain the delivered equipment, and provide training to the plant staff. Thanks to high-quality equipment combined with fast service, we have implemented high-level solutions across different industries and municipalities around the globe: all in all to 85 countries and 1 200 different plants in the last 30 years. As the manufacturer, we take full responsibility for the maintenance of our products. Our team of professional support staff travels to plants all over the world, rectifying problems with equipment and providing on-site support to our customers.

Company details

Find locations served, office locations.

- Business Type:

- Manufacturer

- Industry Type:

- Sludge Management

- Market Focus:

- Globally (various continents)

- Year Founded:

- 1986