Digital Control Corporation (DCC) products

Duplex Pump Controllers

DCC - Duplex Float Switch Controller (DFSC)

The Duplex Float Switch Pump Controller (DFSC) model 12036 is a control and display unit which automatically controls up to two single speed pumps. It is designed to be the heart of a duplex pump control system for lift stations and other fluid pump-down applications. The DFSC provides built-in pump alternation, pump start time delay, and pump disable inputs. It is designed to work with up to five float switches. The controller has six optically isolated inputs for seal leak sensors and thermal overload switches available with most submersible pumps. The DFSC includes the following status indicators on front panel: high alarm light, high alarm horn, low alarm, pump status, seal failure, temperature failure, and floats. The DFSC also includes an RS-232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the unit remote data acquisition, monitoring, and control capability.

DCC - Triplex Float Switch Controller (TFSC)

The Triplex Float Switch Pump Controller (TFSC) model 12064 is a control and display unit which automatically controls up to three single speed pumps. It is designed to be the heart of a triplex pump control system for lift stations and other fluid pump-down applications. The TFSC provides built-in pump alternation, pump start time delay, and pump disable inputs. It is designed to work with up to five float switches. The controller has six optically isolated inputs for seal leak sensors and thermal overload switches available with most submersible pumps. The TFSC includes the following status indicators on front panel: high alarm light, high alarm horn, pump status, seal failure, temperature failure, and floats. The TFSC also includes an RS-232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the unit remote data acquisition, monitoring, and control capability.

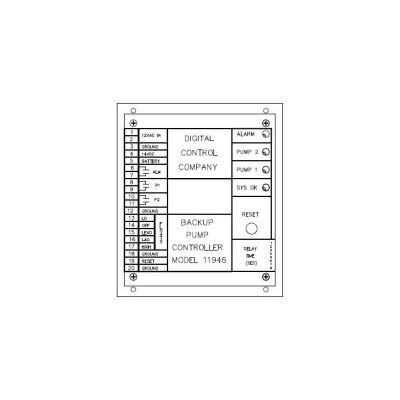

DCC - Backup Float Switch Pump Controllers (BUPC)

The Backup Pump Controller (BUPC) model 11946 is a control and display unit which automatically controls up to two single speed pumps in the event of a primary controller failure. It is designed to serve as a backup controller in a duplex pump control system for lift stations and other fluid pump-down applications. The unit can also function as a primary duplex float switch controller. The BUPC provides built-in pump alternation, pump start time delay, and a system alarm to indicate primary control failure. It is designed to work with up to five float switches. When operating as a backup controller, it will only control the pumps if the primary controller failed to maintain a liquid level within the normal operating limits. If the BUPC senses that the level has exceeded the primary control upper limit, then it will take over and operate the pumps.

DCC - Triplex Backup Float Switch Controller (TBUPC)

The Triplex Float Switch Pump Controller (TFSC) model 12064 is a control and display unit which automatically controls up to three single speed pumps. It is designed to be the heart of a triplex pump control system for lift stations and other fluid pump-down applications. The TFSC provides built-in pump alternation, pump start time delay, and pump disable inputs. It is designed to work with up to five float switches. The controller has six optically isolated inputs for seal leak sensors and thermal overload switches available with most submersible pumps. The TFSC includes the following status indicators on front panel: high alarm light, high alarm horn, pump status, seal failure, temperature failure, and floats. The TFSC also includes an RS-232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the unit remote data acquisition, monitoring, and control capability.

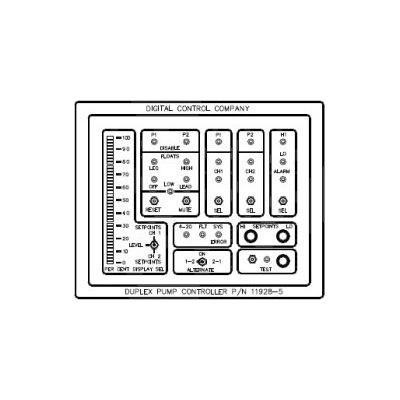

DCC - Duplex Pump Controller

Controls up to 2 constant speed pumps. Supply voltage: 12 VAC. 4-20 mA sensor input. Inputs for float switches and pump disables. Pumps and alarms output relays: 15A at 125 VAC. RS-232 serial port.

DCC - Triplex Pump Controller

The Triplex Pump Controller II (TPC2) model 11967-5 is a control and display unit which automatically controls up to three single speed pumps. It is designed to be the heart of a triplex pump control system for lift stations, water tanks, and other fluid pumping applications. The TPC2 provides builtin pump alternation, pump start time delay, high and low level alarms. It can use any level sensing system that generates a 4-20 mA signal proportional to level as well as backup float switches. The TPC2 is also capable of using up to two additional 4-20 mA input signals as backup sensors in the event that the primary sensor fails. The controller automatically detects and uses the sensor type which is present and working. The TPC2 also includes an RS- 232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the unit remote data acquisition, monitoring, and control capability.

Level Measurement

DCC - Bubbler Level Monitor

The Bubbler Level Monitor (BLM) model 12259 is an automatic bubbler type level measurement and display unit that periodically samples the level of most liquids. It operates by forcing compressed air into a bubbler tube with its opening placed near the bottom of the liquid. The BLM measures the pressure required to force air through the tube and generates a 4-20 mA signal which is proportional to the depth of the liquid in addition to displaying the sampled level. The pressure in the bubbler tube is also monitored to detect significant changes in liquid level which may happen between samples. If a change is detected then a new sample is initiated to update the measured level. The unit uses field configurable software that is menu-driven to allow users to change the unit’s sampling rate, offset, span, and level alarms without additional programming.

DCC - Bubbler Level Transmitter

The Plant Air Bubbler I,evel Transmitter (BIT) model 12138-P is an automatic bubbler type level measurement system. It operates by forcing existing plant air into a bubbler air tube at a constant rate with its opening placed near the bottom of the liquid. The pressure required to force air through the tube is proportional to the depth of the liquid. The BIT measures this pressure and generates a 4-20 mA signal which represents the depth. The unit includes a built-in purging cycle to keep the bubbler line clear from obstructions. The BLT also includes an KS-232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the system remote data acquisition, monitoring, and control capability.

DCC - Bubbler Level Transmitter

The Plant Air Bubbler I,evel Transmitter (BIT) model I2138-P is an automatic bubbler type level measurement system. It operates by forcing existing plant air into a bubbler air tube at a constant rate with its opening placed near the bottom of the liquid. The pressure required to force air through the tube is proportional to the depth of the liquid. The BIT measures this pressure and generates a 4-20 mA signal which represents the depth. The unit includes a built-in purging cycle to keep the bubbler line clear from obstructions. The BIT also includes an KS-232 serial communications interface designed to support SCADA systems using a variety of Modbus based communication devices giving the system remote data acquisition, monitoring, and control capability.

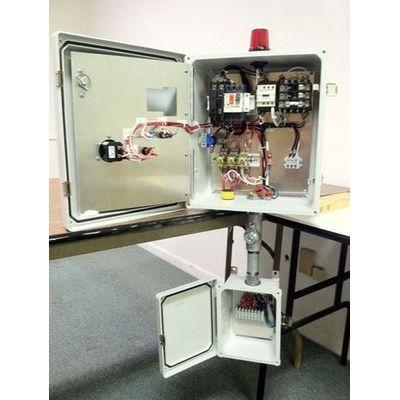

Custom Control Panels

DCC - Custom Control Panels

DCC is an Industrial Control Panel manufacturer certified to Underwriters Laboratories® (UL) 508A Standards (File No. E222066). Each custom control panel is custom built to specifications and thoroughly tested prior to shipment. DCC has built hundreds of custom control panels primarily designed for water and wastewater collection and distribution systems among other industrial applications.