DRYCAKE - TWISTER DEPACKAGER products

Twister - Model Seditank - Manure Post Depackager

Remove grit as well as plastics prior to biogaz reactor, The grit, heavy inert fraction, exits Depackagers with the organics outlet. Grit represents an important maintenance cost for Biogas Reactors, and is undesirable in the final digestate. The Seditank removes the grit and plastics prior to entering the Biogas Reactors.

Twister - Model DEGLASSER - Glass Depackager

GLASS DEPACKAGING, WINE, BEER, MAYO, SAUCES.

Twister Cleanpress - Inline Strainer Screen

The Cleanpress® removes residual plastics after a Depackager. The Cleanpress® is an inline strainer screen with compaction to extract residual contaminants such as plastic from the digestate or organic soup produced by a depackager. The Cleanpress can be installed in-line with digester or fed by pump. The Cleanpress is equipped.

Twister - Digestate Dryer

DRYCAKE and TEMA Process join force into a strategic alliance to elevate digestate drying in USA and Canada. This strategic alliance will manage the digestate output from the biogas plant. The TEMA Process Fluidized Bed dryer are used for energy-efficient drying of the digestate using waste heat of biogas plants. The digestate is dried to reduce weight, reducing storage and transport costs. The dried material can be converted either into organic fertilizer or fuel.

Water and Wastewater Screening Systems

Model DSS - Screw-Screen

Screw-screens are integrated machines consisting of a screen, a shaft-less spiral and an compaction unit. During operation, solids within the incoming flow will progressively collect onto the screen mesh and cause it to gradually blind. The upstream water level will rise and at a predetermined level, the spiral will be activated. Brushes fixed to the periphery at the lower section of the spiral will then clean the screen mesh and convey the solids up to the compaction zone.

Model DSS-V - Vertical Screw-Screen

Designed to be installed into sumps, manhole chambers, underground chambers, pumping stations, etc. DRYCAKE vertical screens provide a solution to facilitate lifting, washing, dewatering, compaction of solids and improving the performance and reliability of drainage systems.

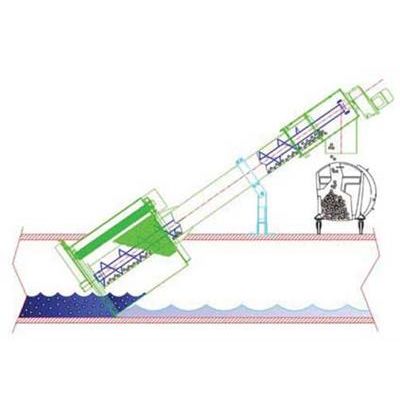

Model DRD - Rotary Drum Screw-Screen

DRD Rotary Drum Screw-Screens are integrated machines consisting of a screen, a screw conveyor and compactor. During operation, solids within the incoming flow will enter into the drum screen and progressively collect onto the screen mesh and cause it to gradually blind. The upstream water level will rise and at a predetermined level, the drum screen and screw conveyor will activate and rotate immersing a clean section of the screen into the effluent.

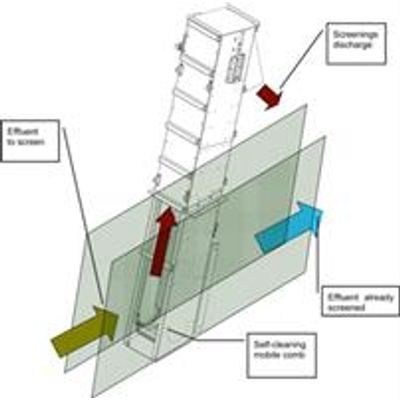

Model V1 1701 - Perfoplate Wastewater Screen

The PERFOPLATE is the ideal machine for the pre-treatment of the wastewater. The PERFOPLATE was designed with attention to the critical design points.

Model DBS - Vertical Bar Screen

Screen is composed of bars obstructing the solids present in the effluent. Cleaning of the screen is achieved by means of 2 rakes with teeth moved by 2 chains.

Screen Washer Compactor

DRYCAKE`s technical department is able to develop all the required design activities from feasibility to as-built. Process Validation can be validated using our lab or on-site pilot services.Our equipment is manufactured in high quality Stainless Steel, and is fully customizable according to project requirements and needs.