Duroair Technologies Inc. services

Solutions

Cleanroom Solutions

Ensuring quality control while balancing long-term construction with short-term cutting, welding, or surface prep and spraying tasks is an ongoing logistical challenge. Navigating these cellular workflows is critical for aerospace OEMs, ship and boat manufacturers, and for operations conducting prototyping and R&D. How do you cost-effectively isolate manufacturing processes to keep damaging elements out and clean air around each workpiece?

Painting & Coating Solutions

Whether your focus is aesthetics quality control or corrosion protection, surface-prep dust can wreak havoc on your coating and painting processes. Add the impact of conventional industrial spray booths on intermittent applications and material handling, and you have a recipe for the bottom-line blues.

Dust Collection Solutions

Dust poses serious risks to both worker health and your entire facility. Grinding and blasting, cutting and sanding, and working with composites, metal, or stone produce a wide range of potentially hazardous dust that can compromise product quality and settle into every crook and crevice of your valuable machinery. Duroair can safeguard your employees and operations from dust exposure and help you go beyond OSHA compliance with our best-in-class filtration technology.

Metal Cutting Solutions

Non-Destructive Testing Solutions

Oil Mist Collection Solutions

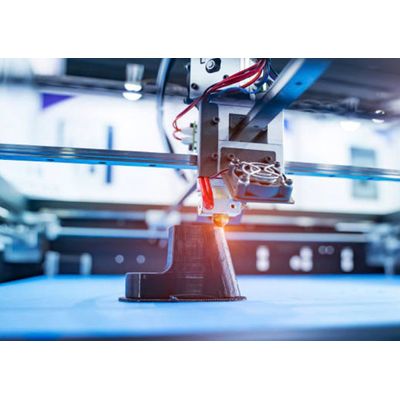

Clean Air Solutions for Safe Additive Manufacturing

Additive manufacturing has the potential to help manufacturers minimize materials and energy usage, thereby reducing waste. Yet, for all the 3D excitement, there’s been very little public focus on the potential indoor air hazards of 3D printing at the industrial level, which can release volatile organic compounds (VOCs) and potentially toxic dust into the air. What if manufacturers had a proactive air filter for dust, to destroy these indoor air hazards before they’re released into a manufacturing facility?