- Home

- Companies

- Water and Wastewater

- Water Treatment

- Dynatec Systems Inc.

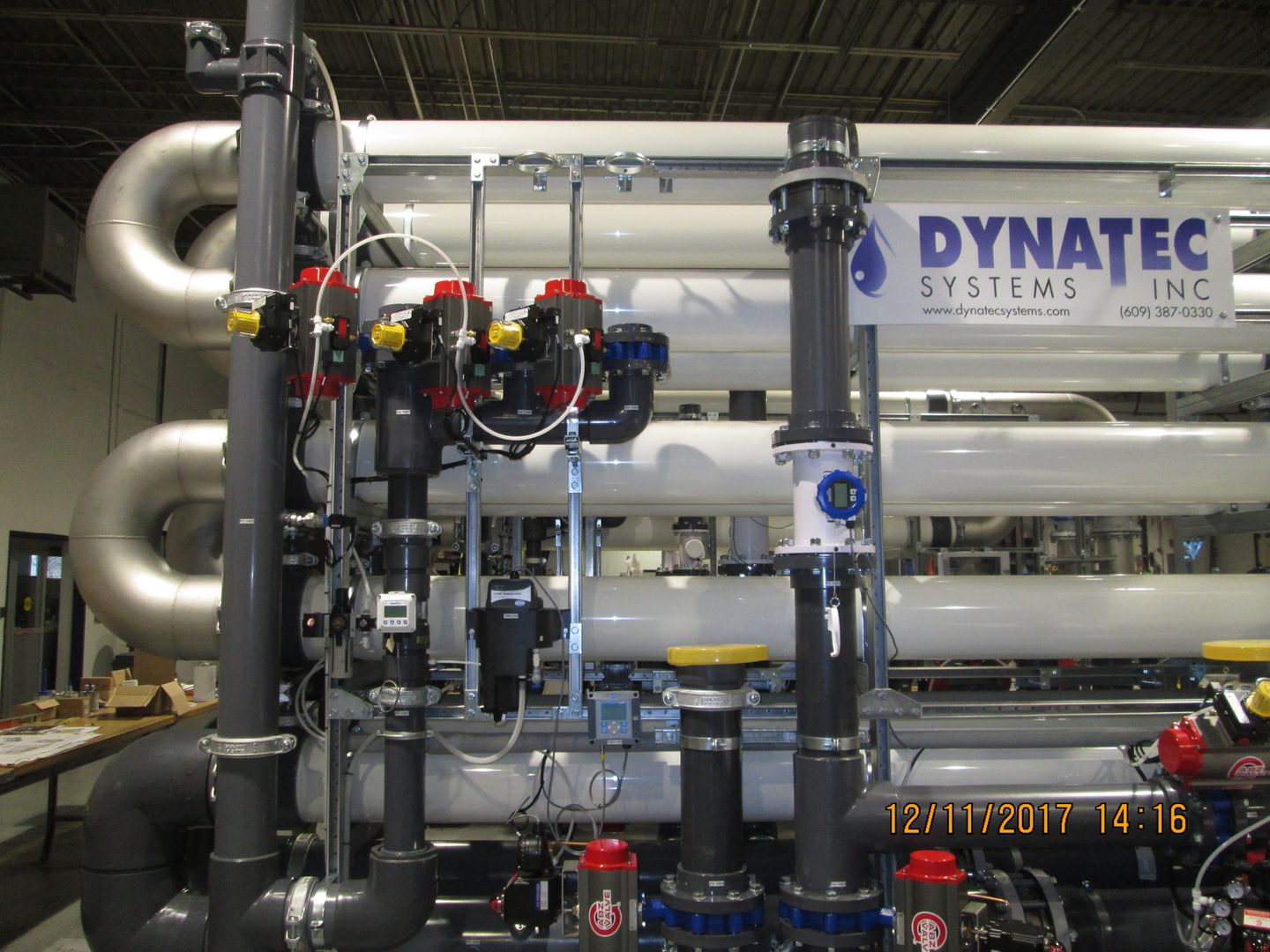

Dynatec Systems Inc.

Dynatec Systems has been designing and manufacturing wastewater membrane treatment systems since 1978. Since 1978, our business has been dedicated to solving industrial wastewater problems. Dynatec’s objective and commitment is to guarantee customer satisfaction by providing comprehensive integrated solutions and supplying high quality equipment and systems for the treatment of industrial and commercial wastewater. We have solved a broad range of wastewater problems. The solutions have included systems as simple as pH control or oil/water separation, to full-scale chemical/physical, biological and membrane systems (microfiltration, ultrafiltration, nanofiltration and reverse osmosis). Dynatec designs and provides systems to produce the desired performance at the lowest overall operating costs. Dynatec has successfully designed, engineered, and installed hundreds of wastewater treatment and recovery plants throughout North America since 1979 and in the world.

Company details

Find locations served, office locations.

- Business Type:

- Manufacturer

- Industry Type:

- Water Treatment

- Market Focus:

- Internationally (various countries)

- Year Founded:

- 1978

Most popular related searches

- Aerospace & Air Transport

- Aerospace & Air Transport - Airports

- Agriculture - Fisheries

- Agriculture - Poultry

- Chemical & Pharmaceuticals

- Chemical & Pharmaceuticals - Petrochemical

- Chemical & Pharmaceuticals - Pharmaceuticals

- Environmental

- Food and Beverage

- Food and Beverage - Beverage

- Food and Beverage - Food

- Food and Beverage - Winemaking

- Leather & Tanning

- Manufacturing, Other

- Metal

- Metal - Metal Finishing

- Mining

- Oil, Gas & Refineries

- Oil, Gas & Refineries - Refineries

- Printing

- Textile

- Waste and Recycling - Hazardous Waste

- Waste and Recycling - Landfill

- Waste and Recycling - Municipal Waste

- Waste and Recycling - Waste Management

- Waste and Recycling - Waste Regulations and Compliance

- Water and Wastewater

- Water and Wastewater - Chemical Water Treatment

- Water and Wastewater - Stormwater

- Water and Wastewater - Water Filtration and Separation

- Water and Wastewater - Water Treatment