ECOMAX SOLUTIONS PVT LTD products

ECOMax-HE ATCS - Automatic Tube Cleaning System

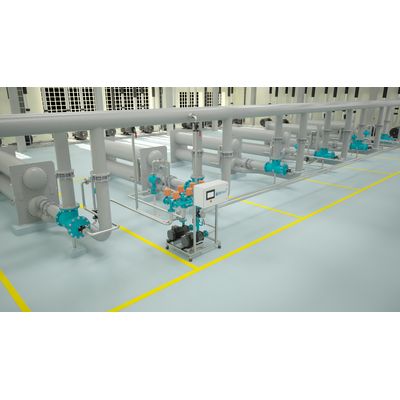

ECOMax-HE helps to keep the heat exchanger tube always clean online, thereby achieving the highest level of performance in the Water Cooled HVAC Chillers, Power Plant Condensers and Process Heat Exchangers. It works on the principle of injection and collection of cleaning sponge balls into the heat exchanger tubes. Salient Features: • Fully automatic, no manual intervention required • Cleaning is done on continuous basis online • Zero ball loss system • Ensures 100% clean tubes • Ball replacement required only once in 3-4 months • Single System for Multiple Chillers/ Condensers • User Friendly • No water wastage from the system • No mixing of CW inlet and CW Outlet Water during operation • Green Technology Benefits: • Results in 10-25% energy saving in HVAC chillers • Increases cooling capacity of HVAC Chillers • Improves condenser tube life • Improves Compressor Life • Avoids costly shutdown and downtime • Eliminates offline cleaning completely • Avoids harmful chemicals thatECOMax-HE - Automatic Tube Cleaning System for Heat Exchangers

ECOMax-HE is a robust and efficient solution engineered to tackle fouling in shell and tube heat exchangers. This automatic tube cleaning system utilizes sponge balls injected through the tubesheet to clean scale deposits within heat exchanger tubes. Featuring a dual-pump mechanism, ECOMax-HE® executes periodic batch operations controlled by a PLC, ensuring minimal maintenance while optimizing performance. It suits diverse applications from HVAC systems to power plants, offering energy savings up to 20% for chillers and a 5% power output increase in power plants. The system enhances cooling capacity, extends condenser tube life, and reduces specific steam consumption without relying on offline cleaning. With a payback period of less than two years, subject to local conditions, and decreasing harm from cleaning chemicals, it's well-suited for industries aiming to bolster efficiency and sustainability.

ECOMax-CT - Electrolytic Cooling Tower Water Treatment System

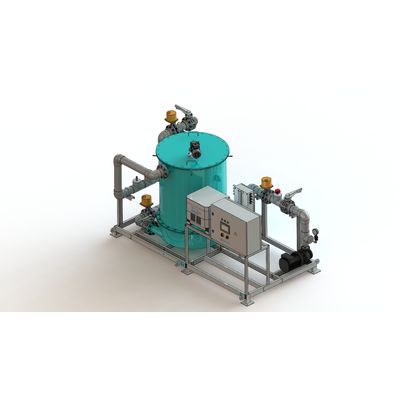

The ECOMax-CT is an advanced electrolytic water treatment system specifically designed for cooling towers, emphasizing a chemical-free approach. By leveraging the process of water electrolysis, the system reduces blowdown water consumption by up to 80%, promoting sustainability and cost efficiency. Operating within the sidestream, it utilizes electricity to treat circulating water, generating oxidants to combat bacterial and algae growth while ensuring minimal use of chemicals. This technology supports higher TDS/conductivity levels without significant fouling risks, thanks to its self-cleaning mechanism aided by a scraper and TDS controller. Additionally, the system features an auto-backwash sidestream filter for suspended solids. Specially tailored sub-categories address the needs of HVAC and large cooling towers over 2000 m³/hr, enhancing efficiency and reducing scaling. Overall, ECOMax-CT® is ideal for applications in HVAC, power plant, and process cooling towers, offering solutions that diminish corrosion, lower energy consumption, and extend equipment lifespan.

ECOMax-CH - Electrolytic Chilled Water Treatment System for Closed-Loop Circuits

The ECOMax-CH Electrolytic Chilled Water Treatment System is engineered to treat chilled water in closed-loop circuits, mitigating issues such as fouling, corrosion, and microbacterial growth through the use of electrolysis. This system is particularly important for maintaining the integrity and performance of heat exchange equipment like AHU coils, FCU coils, filters, and pipes. By generating free chlorine and other oxidants, it curbs microbial activity and sustains a slightly alkaline pH in the circuit, effectively minimizing corrosion risks. The system's advanced filtering capabilities ensure the removal of suspended particles, further enhancing water purity and system efficiency. As a chemical-free solution, it diminishes operation and maintenance costs while supporting a wide array of applications, from commercial buildings and hotels to hospitals and pharmaceutical industries, where maintaining system integrity and reducing downtime are critical.

ECOMax-CT®-Electrolytic CT Water Treatment System

ECOMax-CT®; Electrolytic CT Water Treatment System is a chemical free water treatment for cooling towers and it works on the principle of electrolysis of water that reduces upto 80% blow down water consumption. The process is different from other non -chemical water treatment systems and it follows: The system works in the sidestream of the cooling towers and uses only electricity to treat the circulation water. In the electrolysis process, DC current is passed through Anode and Cathode. At cathode OH- ions are generated, which creates high pH environment at the walls of cathode. This results into precipitation of calcium and magnesium salts present in the water into the electrolytic reactor. Chlorine gas and other oxidants are generated at anode which help reducing bacterial and algae growth in the cooling tower.ECOMax-RM - Remote Monitoring System for Chillers

The ECOMax-RM Remote Monitoring System is designed to enhance chiller performance by employing cloud-based technology for real-time monitoring and management. It offers a user-friendly interface to evaluate chiller efficiency through the continuous analysis of critical parameters such as temperature, flow, and energy consumption. Data collected from field sensors is processed in the cloud and visualized on an informative dashboard, facilitating diagnostics and decision-making for optimal chiller operation. Operators can access precise trends and reports, leading to significant energy cost reductions and minimized maintenance expenses. The system's scalability and compatibility with various locations allow multiple users simultaneous access, while its integration with Building and Central Plant Management Systems further streamlines monitoring. ECOMax-RM enriches equipment reliability with diagnostic reports and supports sustainability and profitability goals.