econ industries services GmbH products

VacuDry® - Treatment of NORM Waste

Natural Occurring Radioactive Material (NORM) consists of materials enriched with radioactive elements that are found in the rock formations and brought to the surface through oil and gas exploration or mining activities. NORM requires strong expertise to ensure safe disposal and compliance with environmental regulations. Since more than 20 years econ’s VacuDry® technology physically separates the different fractions of hazardous wastes through thermal separation, braking up a difficult to handle radioactive, oily sludge matrix into clean water, clean oil and dry mineral solids. The radioactivity remains in the solid residue. The extracted water and oil is free of any radioactivity and allowing it to be reused. As a result, the mass and volume of the NORM waste is significantly reduced. Secondly, once the solids are oil-free, they can be immobilized using cement or geopolymer. The NORM material is now ready for safe long-term storage.Technology

econ - Mobile Mercury Conversion Units

Hundreds of tons of elemental mercury - amongst others the largest ever existing mercury stockpile of more than 400 tons - have already been converted to mercury sulphide and finally stored, based on our unique mobile solutions for mercury conversion. Under nitrogen atmosphere liquid mercury and Sulphur powder react in a hermetically closed reactor. Continuous, intensive mixing during the process ensures complete stoichiometric reaction to form mercury sulphide, enabling its safe final disposal. In terms of traceability, flexibility, safety and eco-friendliness of the offered mercury waste disposal solutions, our solution is unrivalled. Mobile units and on-site mercury conversion are ideal for companies that want to take more control and ensure that their excess mercury is no longer traded or disposed of in a vague or questionable manner.

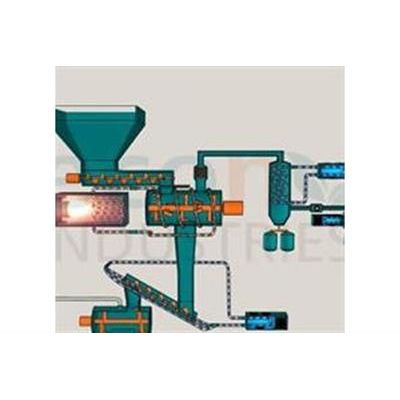

econ - High Temperature Treatment Unit

The econ High Temperature Treatment Unit is a continuous process designed for the treatment of catalysts and activated carbon contaminated with mercury, mercury sulphide (HgS), sulphur, and hydrocarbons. The HTTU uses a direct fired thermal oxidation technology for the high temperature (700 - 1000 °C) destruction of mercury compounds and oxidation of sulphur and hydrocarbons. During the process, the material is continuously mixed to ensure homogenous quality. The treated catalysts are discharged and cooled down. After the treatment, the mercury-free catalysts can be sent to downstream metal reclamation. The off-gas is treated in several treatment steps to remove dust, mercury, and S02 from the off-gas stream. An activated carbon filter ensures the emission limits are met at all times. The wastewater generated in the off-gas treatment is treated in a three-step filtration process in which the mercury is removed prior to discharge into the sewage system.

VacuDry® - Indirect Heated Vacuum Distillation Technology

econ VacuDry - Vacuum Distillation Process

Greatest benefits of the econ VacuDry technology: Highly efficient thermal desorption is achieved due to a unique vacuum and indirect thermal oil heating system. Recovery of valuable resources rather than incineration. Highest safety and environmental protection standards – due to the vacuum process, nitrogen blanketing and full procedure control. Lowest emission of any desorber type – due to the vacuum system, activated charcoal filter and thermal oil heating system. ATEX certified technology, approved by German TÜV. Design standards according to EN, ASME, GOST-R or individual specification.

econ VacuDry® - Mercury Waste Treatment Units

econ industries is the only company worldwide which operates a complete mercury waste recovery and treatment centre; suitable for processing all types of mercury waste on an industrial scale. The econ industries mercury waste centre combines only the safest and most environmentally friendly technologies available. Utilising our equipment and technical knowledge, we are able to safely separate mercury from wastes and, if required, stabilize the pure mercury for safe final disposal.

econ VacuDry - Waste Treatment Mobile Solutions Unit

With the new VacuDry0 1,500 and VacuDry® 12,000 series, the innovative VacuDry® technology is now available as fully mobile unit. This incredibly flexible design still offers all of the advantages that our customers have come to expect, many of which lead the market in the field of industrial waste treatment. The mobile plants consist of completely pre-assembled, containerized and skid-mounted modules that can be easily transported and put into operation. After one project is successfully completed, the mobile VacuDry® unit can be moved easily to the next project in less than four weeks.

econ VacuDry - Vacuum Dryer

The VacuDry system is available in different sizes with different throughput capacity. Depending on the needs of our costumers we decide which is the best option. VacuDry plants are equipped with a varying number of vacuum dryers, totalling a gross volume of 1,500 to 12,000 litres. The dryers work in a batch-wise process. The batch time depends on the feed material consistency, as well as various adjustable parameters and operating conditions.

econ VacuDry zerofuel - Energy-efficient Solution for Drill Cuttings Treatment, Contaminated Soil Treatment & Oil Sludge Treatment

During drilling operations huge amounts of oil sludge, drill cuttings and oil contaminated soils are produced. Often these wastes are stored near the drilling rig for many years and finally have to be treated and/or disposed of professionally. The latest development at econ industries is an environmentally friendly, energy self-sufficient and very cost-effective technology for the treatment of these wastes.

Other

VacuDry® - Oil and Metal Recovery from Grinding Swarfs

A combination of rising prices for resources and the improvement in technology make treatment of mill scale and grinding swarf an extremely environmentally friendly and economical solution. The first VacuDry® plant for the recovery of oil solvents and metals from sludges began operating in autumn 2012.

VacuDry - Soil Remediation Plant for Hydrocarbon Contaminants

Remediation of hydrocarbon contaminants from oil lagoons and refinery waste; In 2007 econ industries delivered an indirectly heated thermal desorption plant to a client in Kuwait. The plant was designed to treat various types of waste with hydrocarbon contaminant content, in particular refinery waste, oil lagoons and down hole drilling waste. The aim is to recover the waste hydrocarbons from the soil/sand and remediate the lagoons of their contaminants. Due to the natural evaporation of volatile components at air temperatures in excess of 50 °C, the waste primarily consists of high boilingpoint hydrocarbons. This means product temperatures up to 350 °C had to be realised. There-fore a heating unit using thermal oil of 400 °C was incorporated into the plant. To comply with the ATEX regulation for material with the temperature class T3, all equipment was specially designed for that purpose. The complete plant was certified by the German regulatory body TÜV.