Ehrfeld Mikrotechnik GmbH products

Ehrfeld Mikrotechnik - Modular MicroReaction System for Process Development

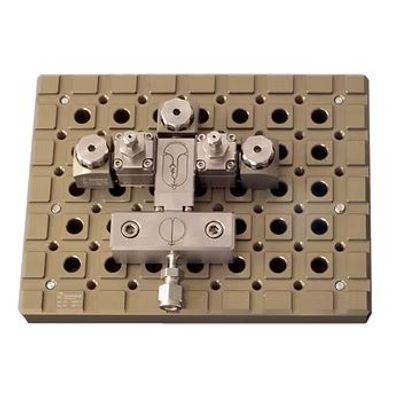

The Modular MicroReaction System (MMRS) by Ehrfeld Mikrotechnik is an advanced platform designed to facilitate process development in research and development environments. This system comprises over 60 unique modules, including microstructured mixers, reactors, and heat exchangers, allowing for tailored and flexible configurations adaptable to various chemical processes. The MMRS is ideally suited for handling highly exothermic or hazardous reactions, showcasing an impressive ability to precisely monitor critical parameters like temperature, pressure, and flow rates. With an innovative modular design, the MMRS offers seamless scalability from laboratory to pilot and production scales. Its components boast robust construction and user-friendly maintenance, facilitating thorough dismantlement without specialized tools. Additionally, LabManager and compatible units enable effortless automation. This system provides a unique entry point for research institutions and industrial R&D into continuous reaction technology, enhancing process efficiency and safety.

Ehrfeld ART - Millistructured Plate Reactors

Our ART® reactors are millistructured plate reactors and they are highly innovative as they are characterized by excellent heat transfer, optimal residence time distribution and faster mixing compared to conventional technology. As a result, this leads to a significant process intensification in terms of yield, costs and safety. ART® reactors can be completely dismantled, which simplifies their cleaning. Thanks to their robust design, metallic material and modular set-up, these compact devices are ideally suited for a wide range of reactions – from the research and development all the way up to production. In addition, they enable effective process control with process analysis technology, which can be integrated with ease.

Ehrfeld FlowPlate - Microreactors for Efficient Process Intensification

FlowPlate microreactors offer a versatile solution specifically designed to tackle the challenges faced by the pharmaceutical and fine chemicals industries, such as the need for small, adaptable production quantities with high-quality demands and rapid market introduction. These reactors, which are developed by Lonza and distributed worldwide by Ehrfeld Mikrotechnik, allow for the development and production of active pharmaceutical ingredients (APIs) and fine chemicals. The modular design of the reactors permits easy scaling from laboratory to production scale with flow rates up to 20 L/h. The units can be operated up to 100 bar and 200°C, presenting new processing opportunities while maintaining safety through rigorous cGMP standards. Each reactor offers a unique, closed one-channel design that avoids dead volume and facilitates easy cleaning and maintenance, making them suitable for campaigns requiring rapid transitions between different processes.