EKOMVO s.r.o. products

BIological Treatment - Aeration Systems for Nitrification and Denitrificattion

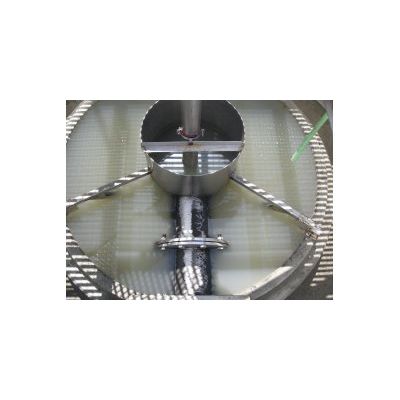

Aeration system EKOMVO is used for aeration and hydraulic agitation of tankages, especially at communal and industrial waste water treatment plants, eventually at intensive fish farming. Oxygen transfer into waste water is done by suitable aeration membrane with fine-buble or medium-buble perforation, according to need. Membrane material is modified polyurethan, especially resistant agains microorganisms and hydrolysis influences. Intensive aeration is necessary at biological waste water treatment to ensure sufficient quantity of air for microorganisms biomass, which decompose waste water contaminants and ensure puryfying effect by its metabolic activity. Membrane by itself is made in such thickness, to ensure long-term operating life and at the same time to be characterized by high oxygen transfer into waste water ability. These parameters, in combination with using of suitable anchorage and fixation materials, guarantee long-term operating life.

Container WTP

The container WTPs are sized along with the jobsheet ATV-A 126 in accordance with ČSN 756402 and ČSN 756401 and with taking into account the directive ATV-H-254 for combined WTP. The outer dimensions of the container WTPs" tank correspond with ISO standard for containers with height of 3,0 m. The tanks of the container WTPs are made of the sheet steel with thickness 5 mm, quality ST 37.2 and with the protection against corrosion, or they are eventually made of polypropylene building elements which are haunched due to statical reasons on the construction site. If required, the tanks of the container WTPs can be furnished with light covering made of plastic or glass fibre.

Wastewater Pre-Treatment

Sand Catchers

USE:The vertical sand catcher is used for gravitative catching of the sand contained in the influent water and to consequent removal of the sand. FUNCTION:Wastewater containing the sand and devoid of rough impurities runs into vertical stilling cylinder where the speed of water flow is lowered in such way that sand grains bigger than 0,2 mm start to settle in the settling space of the catcher. Water, devoid of sand particles in above mentioned way, raises up in the annular area and drains thru the trough to the catcher"s outlet. Sand is removed from the catcher by the help of air-lift pump attached to the air source and then the sand is carried to another treatment.The source of the air actuating the air-lift pump is solved together with the customer individually, always with respect to the general technology of WTP. In the case of deep laid sand catchers the drowned pumps tailored to pumping of the mixture of water and sand are used.

Screen Baskets

Ekomvo s.r.o. company is direct producer and supplier of the screens and the screen baskets. The screens and the screen baskets are used for the direct protection of the pumps and the water supply technologies against inflow of the floating and rough impurities at the wastewater treatment plants, pumping stations, etc.

Sludge Management

Sludge Hygienization / Sludge Pasteurization

Equipment consists of recuperative exchanger, pasteurization exchanger and pasteurization container.Equipment works with undrained sludge with dry matter content 5 to 8 %.Non-treated sludge is preheated in recuperative exchanger with utilization of heat recovery from pasteurized sludge.Preheated sludge is warmed by heating water on given pasteurization temperature in pasteurization exchanger (water/sludge).Necessary detention period for sludge hygienization is achieved in pasteurization container.Pasteurization temperature guarantees devitalization of pathogenic microorganisms in given detention period.Pasteurized sludge is cooled down in recuperative exchanger by giving its heat to non-treated sludge before inlet to sludge digester.In mesophillic sludge digester originates energy-rich biogas.From biogas and its burning is received electric energy and warm.