- Home

- Companies

- Electrolytic Technologies USA

- Applications

Electrolytic Technologies USA applications

Traditionally, water utilities have used chlorine gas as the disinfectant of choice in their water treatment plants. However, recent publicly reported chlorine leakages and foreign terrorist attacks have raised concern regarding the safety of this practice.

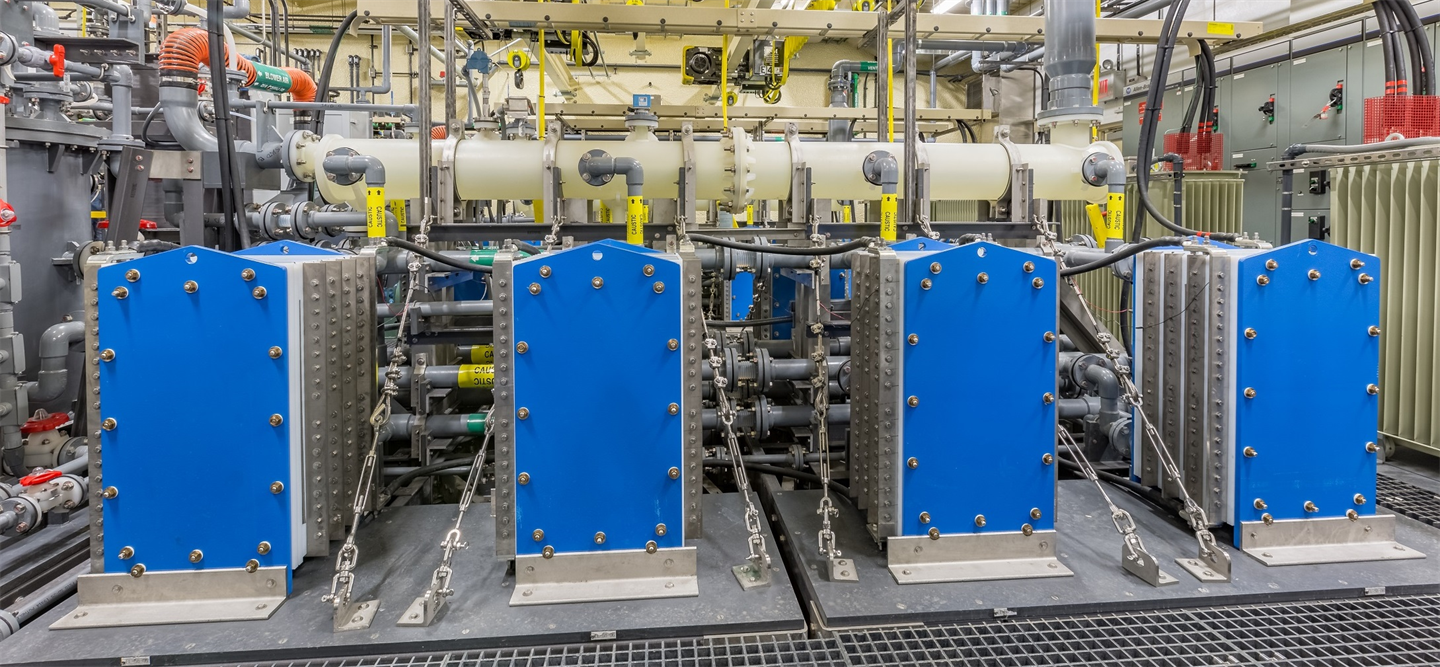

Klorigen™ generators are ideally suited to commercial, municipal or industrial bleach manufacturing, as they are capable of generating the same ultra-pure sodium hypochlorite with the same high quality and 10% to 15% concentration levels as commercial bulk-delivered product.

Klorigen™ systems safely generate the chlorine gas and/or high strength (up to 15%) sodium hypochlorite that is typically used to control biological fouling experienced in cooling water processes in the oil and gas industry. In addition to cooling water applications, Klorigen™ technology is well suited to other oil field applications which include hydrogen sulfide removal, enhanced oil recovery and frac water treatment. Onsite generation allows oil and gas applications to continue using their preferred disinfectant while addressing all the issues related to the transportation, storage and handling of pressurized chlorine gas or sodium hypochlorite. Additionally, Klorigen’s high strength sodium hypochlorite product is produced at concentrations 15-20x higher than other on-site alternatives, providing significant savings in storage, transportation and operational costs.

Traditionally, power plants have used chlorine gas as the disinfectant of choice for treating plant cooling water. However, several publicly reported chlorine leakages have raised concern regarding the safety of this practice.

Chlorine has typically been used as a bleaching agent in pulp and paper mills; however, safety concerns regarding the use of chlorine gas in the industry have recently come under focus. Klorigen™ chlorine generation systems alleviate the risk inherent with the usage of large quantities of pressurized chlorine gas in these facilities.

Klorigen™ systems generate sodium hypochlorite at the same high quality and 10-15% concentration levels as available from bulk commercial suppliers.

Many metallurgical processes require chlorine gas for refining or purification. Klorigen™ chlorine generation systems alleviate the risk inherent with the usage of large quantities of pressurized chlorine gas in these facilities. Klorigen™ systems produce chlorine gas on-demand and under vacuum, eliminating the storage and use of pressurized chlorine gas and the risks associated with chlorine gas currently facing many metallurgical applications. In addition, Klorigen™ systems produce a 15% sodium hydroxide (“caustic”) co-product that is commonly used elsewhere in these facilities. With Klorigen™ on-site generation technology, chlorine and sodium hydroxide may be safely and effectively delivered on-demand, eliminating the threat of a hazardous chlorine release commonly present in the metallurgical industry.