Ennex Solutions GmbH products

Feeding Technology

Ennex - Walking Floor Bunker

The Walking floor bunker enables the regulation of system feed with a variety of input streams. To balance the material flow, a dosing roller can be integrated on the discharge side. The lamella system convey the material toward the dosing roller. The material is made loose by the steel noses on the dosing roller and coveyed to the next belt conveyor. The throughput can be adjusted by the frequency converters of the two motor drives. The lamella system is designed with overlapping wearing metal sheets and guide rails of hard plastic on the bottom face and on the sides. The lamella system is moved in triple groups by means of double-acting hydraulic cylinders.

Pre Shredders

Ennex - Double Shaft Shredders

The speciality of all AMB two shaft shredders is the reversing process of the individually driven shafts, which is controlled by a PLC. During an idle run or when the load limit is reached, one or even both shafts switch their rotational direction and continue working in opposition.

Separation and Mixing Technology

Ennex - Multi Fraction Separators

The pre-treated input material is fed in the middle of an inclined sieve tub, which rotates circularly around two eccentric shafts. The drive consists of two electric motors, which have a common frequency converter to achieve synchronism. The motors and the bearings of the shafts are positioned outside of the waste flow, so that the minimised dust load extends the maintenance intervals and therefore the maintenance costs.

Ennex - Stationary Drum Sieves

Stationary drum sieve machines separate the input volume flow into different output fractions. The project specifications, like kind of waste, throughput and sieve grain define the type and size of AMB drum sieve machines. The product range spreads from one-piece drum bodies with one or more mesh apertures to drum bodies in a solid frame construction with changeable sieve plates. Solid steel plate housings with convenient maintenance openings, closed chutes and connections for dust exhaust reduce the dust- and noise-level to a minimum.

Ennex - Stationary Homogenising Drums

Stationary homogenising drums mix pre-treated waste types and prepare them for the following biological treatment. Different sizes allow the individual adaptation to optimise the throughput and the material remains in the machine. Solid and generously designed drives provide high availability even at low rotation speeds. The feeding with a spiral conveyor ensures a mostly closed drum entry, which improves the addition of sewage sludge or seeping water.

Conveyor Technology

Ennex - Chain Guided & Drum Guided Conveyor

The conveyor technology, developed and produced by AMB, is designed especially for the function of transporting different types of waste:

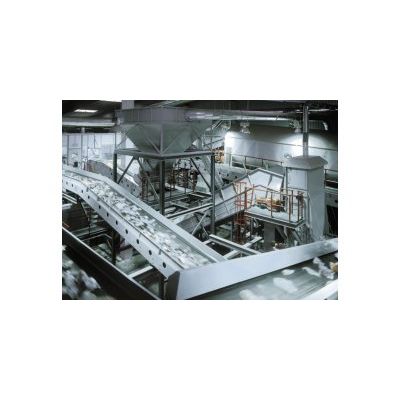

Sorting Plants

Ennex - Industrial Waste Sorting Plant

If the target is an efficient sorting, mixed construction and industrial waste or bulky waste have high requirements for the plant manufacturing. A process combination of grinding, separation and conveying technology have to comply the demanding task to separate the material streams. Downstream visual identifying systems divide the different recyclables fully-automated. On a high level of throughput economical output in combination with high purities can be realized. The manual follow-up control for the quality assurance takes place after the upstream mechanical treatment. Intermediate goods like parts of the fine and residual fraction or high caloric fraction provide the opportunity of different uses. All recyclables (pressed into baled or stored in containers) can be put on the market.

Ennex - Light Packaging Sorting Plant

The charging of the material occurs according to the collection principle by bag openers or underfloor conveyors. The essential sorting consists of an combination of successive turned mechanical processes and manual control afterwards. In the first step large pieces of cardboard, foil, non-packaging made of similar materials and large extraneous materials are removed in the pre-sorting step. Separation technology like drum sieve machines and multi fraction separators separate the input volume flow into various fractions.

Ennex - Pasteboard Paper and Cardboard Sorting Plant

Even if the separate collection of pasteboard, paper and cardboard builds the base for a high recycling quote, only the right choice of technology can lead to an economical sorting plant. Main part here is a automatisation as far as possible. Mechanical separation technology splits different material streams. Conveyor technology straightens out and isolates them, so that an optical identification system can guarantee a varietal separation in defined raw material sorts. In addition to the main product deinking, there are mixed paper and varietal brown and white cardboard. Prior to the final bundling for the ongoing marketing, all qualities are controlled manually again.