ENSEPATEC products

Process Internals

ENSEPATEC - Internals for Horizontal Flow

Ensepatec offers a broad selection of high performance separation internals for horizontal gas flows. These serve in a broad range of industrial, commercial and process applications.

ENSEPATEC - Internals for Wet Scrubbers and Evaporators

Ensepatec offers fully standardized, high-performance and energy-friendly, gas/liquid separations for vertical gas flows. The separators include designs for pre-separation (bulk entrain ment separation for 2-stage systems) and fine separation (to be used as a polishing stage for 2-stage systems or where the process conditions only require a single-stage device). The separators eliminate liquid carry-over caused by high gas velocities to protect downstream equipment and ducting against unwanted effects or corrosion, contamination, or pollution caused by the liquid droplet carryover. These separators have a very low pressure loss and can be operated at gas velocities up to 4.5m/s (900 fpm) under atmospheric conditions, allowing for a mal-distribution of the gas stream up to ±30%.

ENSEPATEC - Mechanical Pre- and Fine Separators

Ensepatec provides enhanced liquid/gas separation equipment for the safe and economical removal of liquid droplets from saturated steam inside a steam drum. The separation internals consist out of pre- and fine separation elements including axial and radial cyclones, flow distributors, vane type separators with coalescer pads for the removal of very fine droplets. Ensepatec designs and selects a suitable combination of separation elements depending on the design parameters including internal drum diameter, the specified liquid levels and the allowable pressure loss. Upon request, Ensepatec conducts computational fluid-dynamics to verify steam flow distribution patterns.

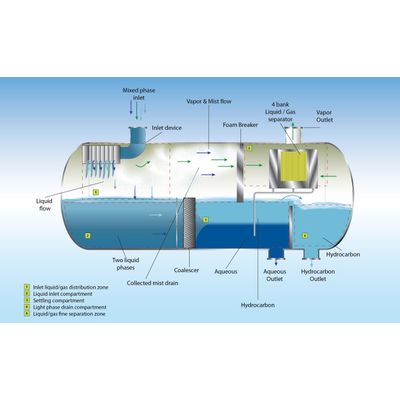

ENSEPATEC - Liquid/Liquid/Gas Separation internals

Ensepatec provides the engineering and design of 3-phase separator internals that target high gas volumes and primary L/L dispersions. Our scope includes the design, engineering and delivery of a) The inlet gas distributor (1). b) The foam breaker along with the the L/G separator (5). c) The dimensional design of the inlet compartmeent, the settling compartment and the product outlet compartment (2), (3), (4). d) The separation of the aqueous and hydrocarbon liquid phases utilizing ether plate pack type or wire mesh coalescers (3). .